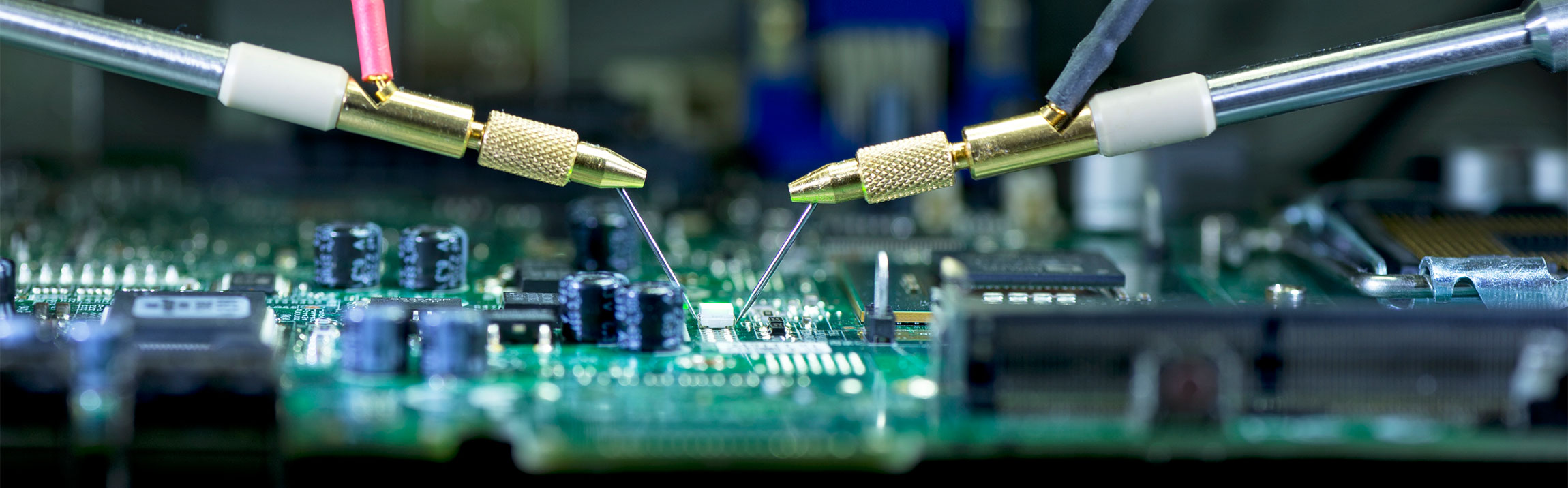

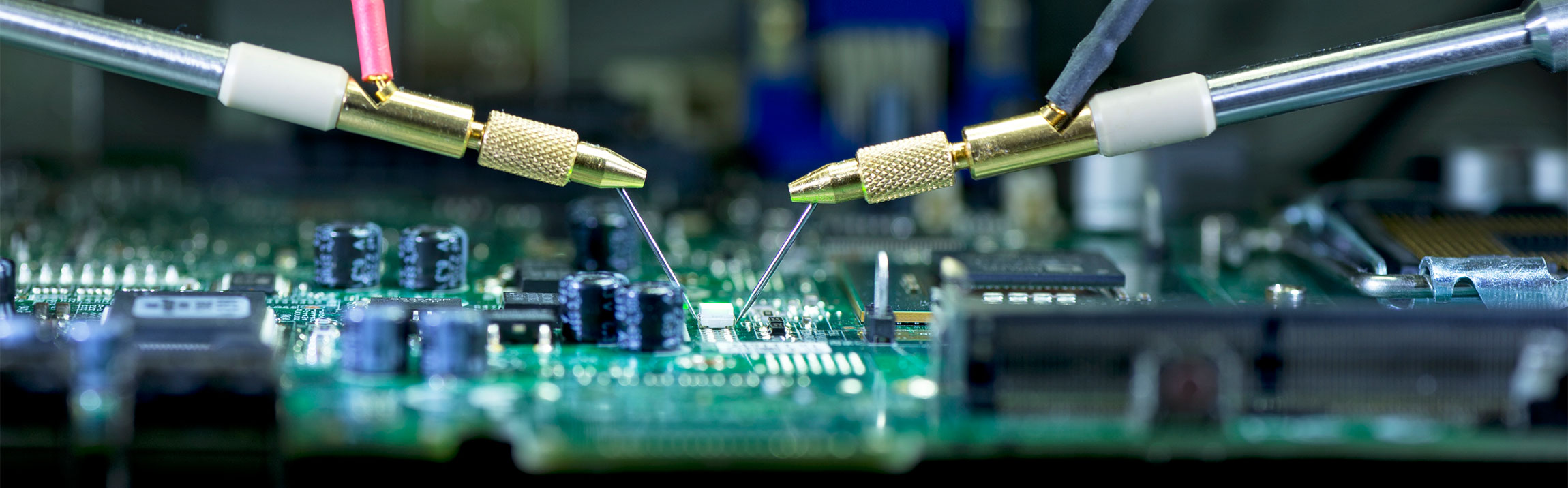

Labs for Test and Analysis of Electronic Components and Systems

Climate and reliability laboratories

Humidity-heat chamber |

|

2 climate chamber |

|

Alternating climate chamber |

|

Precision Temperature Forcing System |

|

Constant climate chamber |

|

High-current laboratory power supply |

|

Electrodynamic vibration system |

|

Tensile/compressive material testing machine |

|

Failure and material analysis

Cross-section analysis

|

|

Stereo and transmitted light microscopes with image analysis |

|

Confocal microscopy & profilometry (optical, tactile) |

|

Atomic force microscopy (AFM) |

|

High-resolution scanning electron microscopes SEM with EDX analysis |

|

IR photon emission microscopy & thermography |

|

X-ray inspection system with high-performance µCT scanning |

|

Reflectometry & ellipsometry |

|

FTIR spectroscopy |

|

MD-PICTS |

|

Source meter, teraohm, and picoamperemeter |

|

Contaminometer |

|

Dip solder bath with SPS control |

|

Bond pull and bond ball/die shear tests |

|

Integrated Circuits

Chip and wafer preparation

High-precision 5-axis CNC milling machine with integrated layer thickness sensor |

|

Chemical-mechanical polishing and grinding system (CMP) |

|

Infrared (IR) laser system |

|

Ion beam etching system "IntlVac Nanoquest I" |

|

ICP-RIE plasma etching system |

|

Scanning electron microscope for chip scanning, "Raith 150 Two" type |

|

Dual-Beam Focused Ion Beam/Scanning Electron Microscope system, "Raith Velion" type, for precise processing and modification of ICs |

|

High-resolution scanning electron microscope, Zeiss Gemini 560 type, for analysis and process control |

|

Additional equipment for processing and process control |

|

Additional equipment for chip analysis |

|

Low-temperature measurements / cryogenics

| Cryostat (temperature <10 mK) |

|

Electro-static discharge (ESD), electrical overstress (EOS), and electromagnetic compatibility (EMC)

Transmission Line Pulser TLP |

|

Human Body Model HBM Tester (component-level testing) |

|

Human Body Model HBM Tester (system-level testing)

|

|

Charged Device Model CDM Tester |

|

Capacitively Coupled Transmission Line Pulsing CC-TLP |

|

Robustness test bench (EMC scanner) |

|

Additional equipment |

|