At Fraunhofer EMFT, we rely on advanced numerical simulations to make electronic connections more efficient, powerful and reliable. In an era of increasingly compact and complex electronic systems, methods such as the finite element method (FEM) offer decisive advantages: they provide precise insights into potential design weaknesses, save development time and reduce costs through virtual testing. Thanks to our innovative approaches, you can rely on optimized and future-proof solutions - from concept development to final product realization.

Optimizing electronic systems through numerical simulations

In electronics, the performance, reliability and efficiency of connections such as solder joints and traces are critical. With the increasing complexity of electronic systems, numerical simulation methods, in particular the finite element method (FEM), are essential for optimizing designs and ensuring robust performance.

Our Services

- Mechanical simulation of stresses and strains in connections, e.g. press-fit pins

- Simulation of complex material behavior such as plasticity, creeping and fatigue in electronics

- Thermal simulation of soldering and other heat related processes

- Transient thermal simulations in cryogenic and heated conditions

- Multiscale simulation of fiber-reinforced composites with complex geometries

- Validation of the results through in-situ experiments

Application Examples

Below you will find an excerpt of past and current projects of the Interconnect Systems team, which include mechanical and thermal simulations.

Quantum Computer Connection

In Munich Quantum Valley (MQV), Fraunhofer EMFT is working on the further development of superconducting qubit platforms. An innovative connector ensures precise connections between flexline and PCB. Thermal simulations are used to investigate the behavior of the connection at cryogenic temperatures.

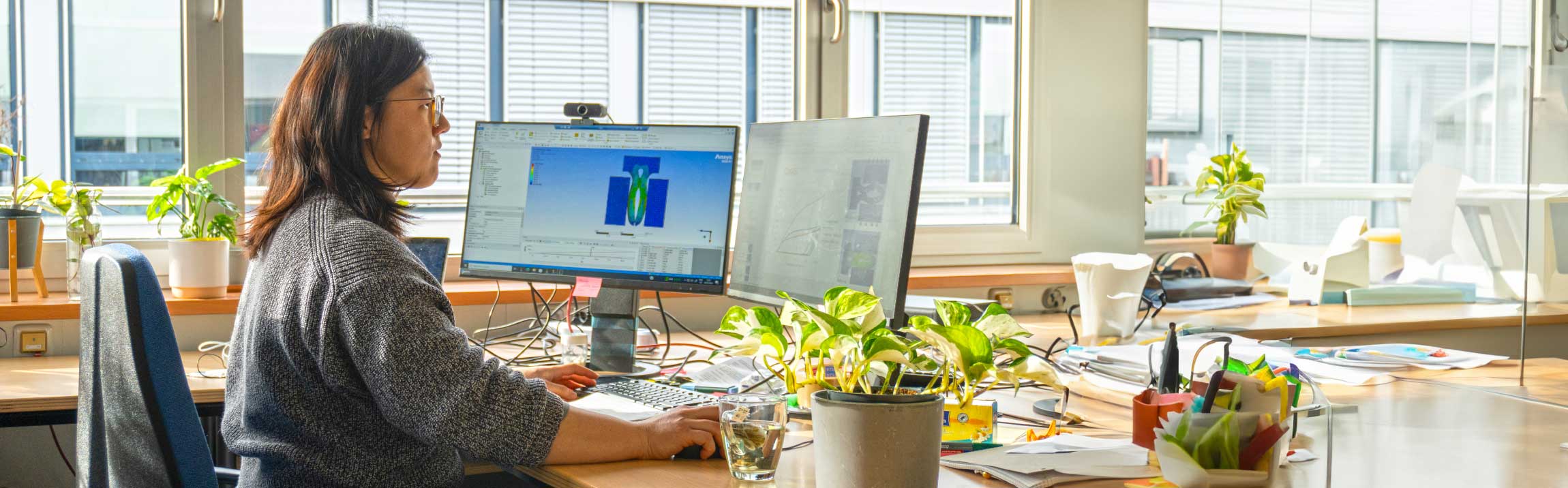

Press-fit technology in drive technology

Press-fit technology offers an innovative solution for contacting processes in drive technology. By developing a test bench and a numerical model, Fraunhofer EMFT analyzes the stress distribution and the press-fit connection process between the press-fit pin and copper sleeve. This enables the optimization of process stability and prevents component damage.

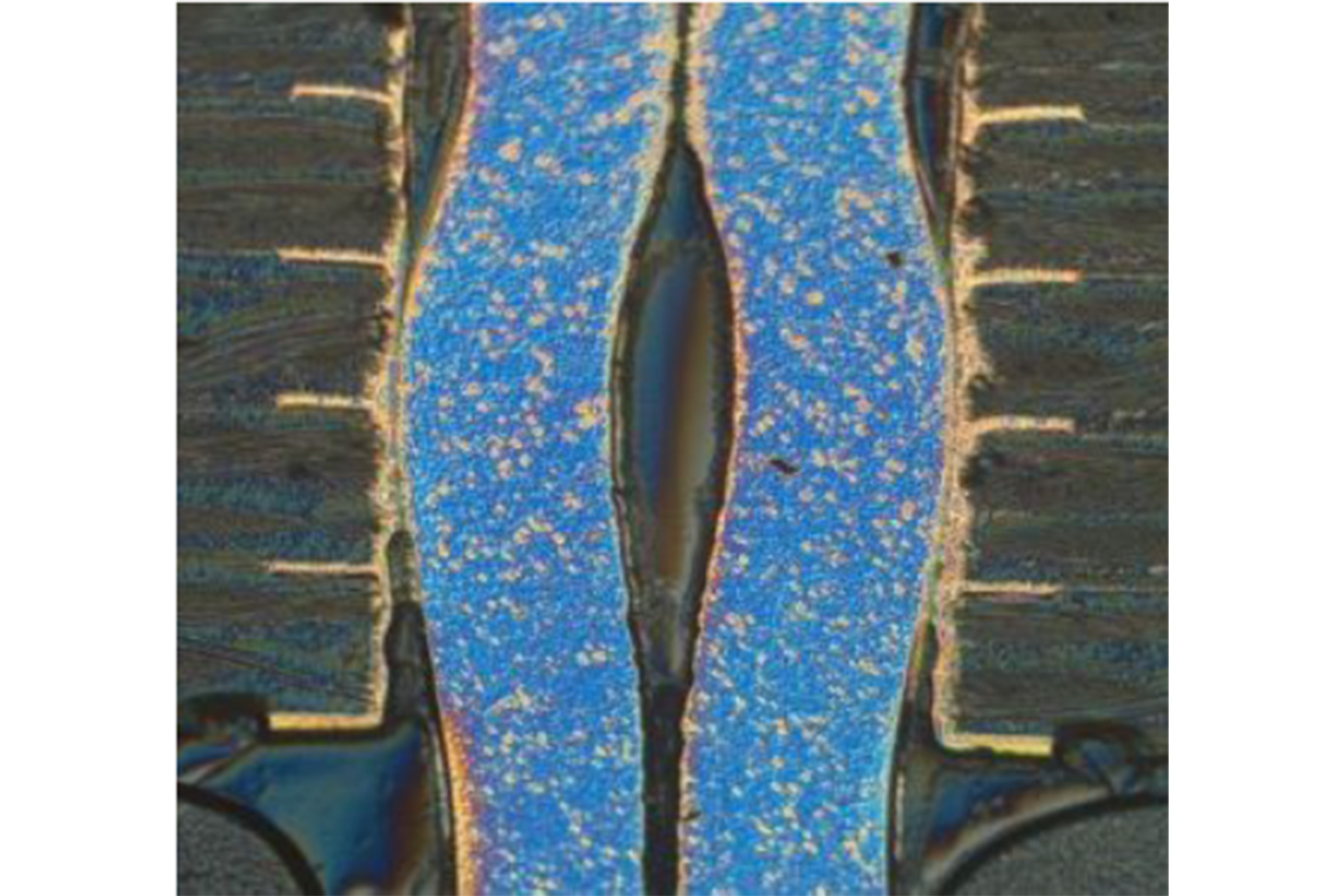

Thermal simulation for soldered joints

The Fraunhofer EMFT team uses thermal simulations to optimize the soldering process and ensure stable electrical connections. By analyzing the temperature distribution and thermal gradients, soldering processes are made more efficient and the quality of the soldered joints is improved.

Heat transfer in copper and thermoplastic in the base material using transient thermal simulation.