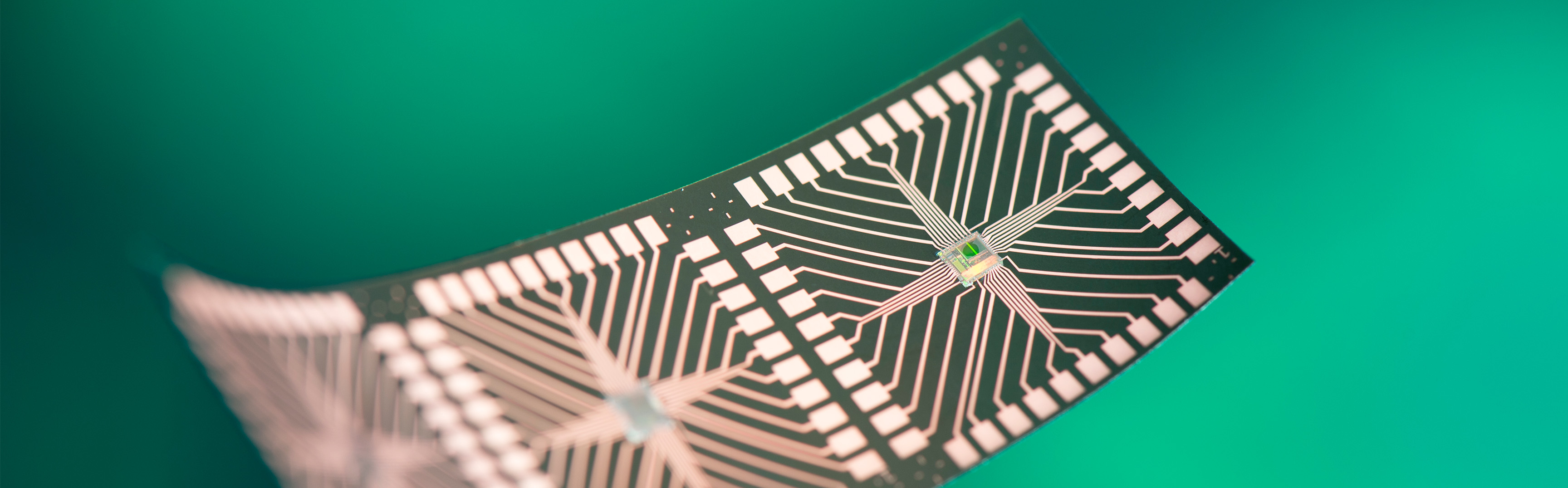

A reliable electrical connection between an integrated circuit (IC) and the surrounding electronics is crucial for chip integration. It represents a key challenge for all microelectronic systems – especially in applications such as chip cards, sensors or portable devices. A proven solution is the so-called ‘mold package’: Here, the chip is embedded in a plastic housing and electrically connected to its environment via external, solderable contacts. We take our approach even further by developing very thin and flexible chip-foil packages.

Electrical Contacts – The Key to Successful Chip Integration

How integrated circuits are reliably connected to their environment

Research at Fraunhofer EMFT focuses on three pioneering approaches to chip assembly:

- Chip-on-film (CoF) or Thin-Chip-Foil Packages

- Chiplet integration

- Chip assembly for quantum computing

Benefits of foil-based chip integration

The integration and electrical connection of IC components on flexible foils is already established in applications such as chip cards. However, the innovative approaches developed by Fraunhofer EMFT open up completely new possibilities in roll to roll (R2R) manufacturing – for cost-effective, scalable and sustainable electronics solutions ‘Made in Europe’. Our many years of expertise encompass the manufacture, handling and characterisation of ultra-thin silicon components as well as the production of high-resolution copper conductor tracks (< 30 µm) on polyimide films.

Research goal: Thin chip foil packages 'Made in Europe'

A key objective is to develop thin chip foil packages using a roll to roll process. This technology opens up new avenues for high-throughput packaging, particularly for flexible and large-area electronic applications. We prioritise process reliability, precision, and European value creation.

Application: Innovations for chiplet systems and quantum computing

Our latest research projects focus on integration technologies for future chiplet systems, e.g. heterointegration within the framework of the APECS pilotline. Here, we develop advanced solutions for assembly on glass interposers (using TGV technology) and for heterointegration with film substrates such as polyimide film. A particular focus is on high-frequency chip systems (RF-on-Flex) for applications in flexible antennas and 360° RADAR systems.

Innovative solutions are also in demand in the field of quantum computing: new packaging and integration technologies enable the connection of numerous ICs on common interposers – often under the demanding conditions of superconductivity and with extremely high precision (< 0.5 µm).