The Fraunhofer EMFT offers over 40 years of expertise in electrical interconnection technology. At the Center for Interconnection Technology in Electronics (ZVE), our focus is on soldering, crimping and assembly and connection technology. We support companies in meeting the increasing demands for reliability, sustainability and efficiency - especially in critical applications such as automated driving functions.

Joining technology for electrical connections

Expert solutions for industry and technology

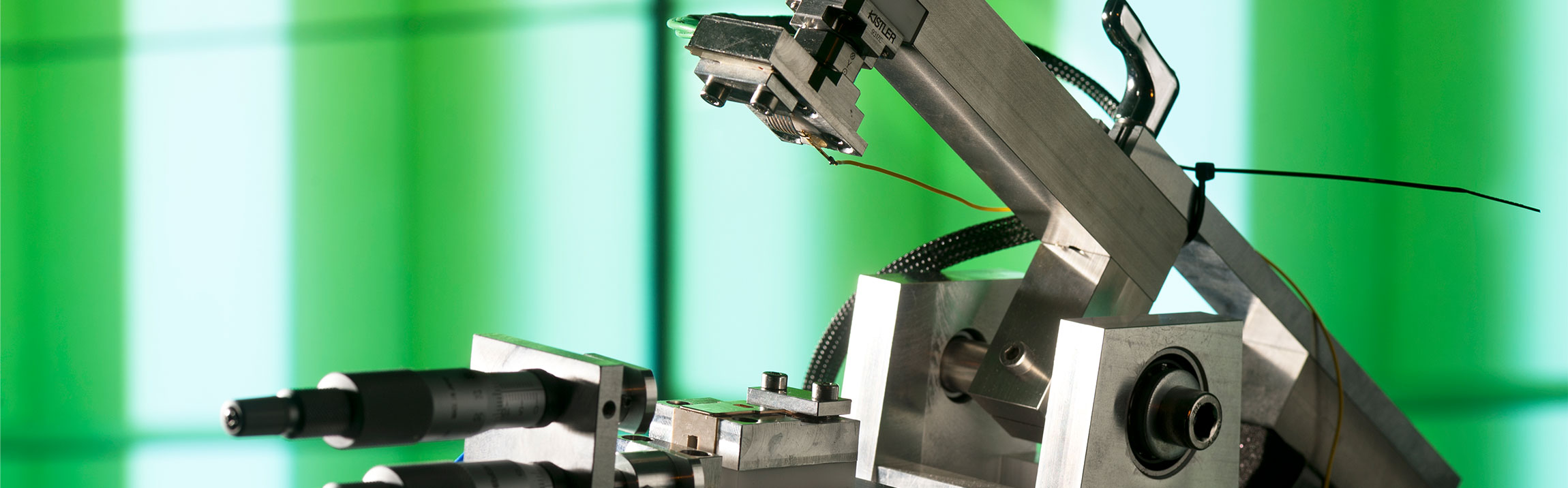

Joining technology is central to the function and reliability of electrical systems. Electrical contacts are created either mechanically by contact forces or by material bonding - for example by soldering, welding or press-fitting. Our aim is to develop optimum connection solutions for your requirements.

Our services in the field of electrical interconnection technology

- Technical advice: We provide comprehensive advice on the best joining techniques for your applications - from the selection of suitable methods to the optimization of processes such as soldering, bonding and welding

- Training courses and workshops: Practice-oriented workshops and training courses provide you and your team with know-how on modern joining techniques such as soldering, bonding and welding

- Quality testing: We test the mechanical and electrical properties of connections - for example using shear, tensile or electrical tests - and provide precise analyses for your products

- Certification support: Our team will assist you with the certification of your products and processes in accordance with industry-specific norms and standards

- Repair of connections: We repair damaged or faulty connections, e.g. by professionally desoldering and re-soldering components

Precise analysis and testing technologies

The (solder) joints are evaluated at the Fraunhofer EMFT using a combination of non-destructive and destructive analysis methods. These include cross-section preparations, light microscopy, scanning electron microscopy and EDX analysis. The reliability of connectors is tested using tests such as fretting corrosion, thermal shock and electromigration tests.

Research and Development

Our ongoing research projects are aimed at developing innovative and future-proof connection technologies:

- Miniaturized solder contacts for space-saving designs

- Simulation of thermal properties in processes and applications

- Power Press-Fit for high electrical power

- Ultrasonic welding as a sustainable joining technology

- Crimping for space applications

- Connectors for efficient data and power networking

- Direct contacting on printed circuit boards to increase efficiency (see FVA project below)

- Cryogenic connection technology for extreme operating conditions

Innovative projects for the industry

Project FVA: Electrical connections between PCBs and PCBs and between PCBs and peripherals are driven by ever smaller installation spaces, higher packing densities and greater reliability. At the same time, environmental and service life requirements such as temperature and vibration are increasing, as is cost pressure. So-called direct contact systems are increasingly being used to meet the space requirements in particular. These systems are characterized by the fact that the PCB itself acts as a contact partner and thus becomes the contact piece.

Project Propin: The project promotes press-fit technology as an environmentally friendly connection method for electromobility. An evaluation method is being developed to analyze the connection quality under mechanical and thermal load. A prediction model links material and process data, which shortens development times and opens up new fields of application for SMEs and start-ups. The Fraunhofer EMFT offers a comprehensive validation method for press-fit connections.