Micro dosing system design requires multifaceted knowledge of fluid mechanics, elastomechanics, electrical engineering, surface physics, chemistry and phase transformation. Understanding the interactions between these factors is essential to enable flawless interaction of all components in a micro dosing system. In order to further optimize the performance and reliability of the micro dosing systems, the researchers are continuously working on new solutions - for example, in the management of bubbles, particles and counterpressures, monitoring the dosing of the smallest quantities or chemical resistance.

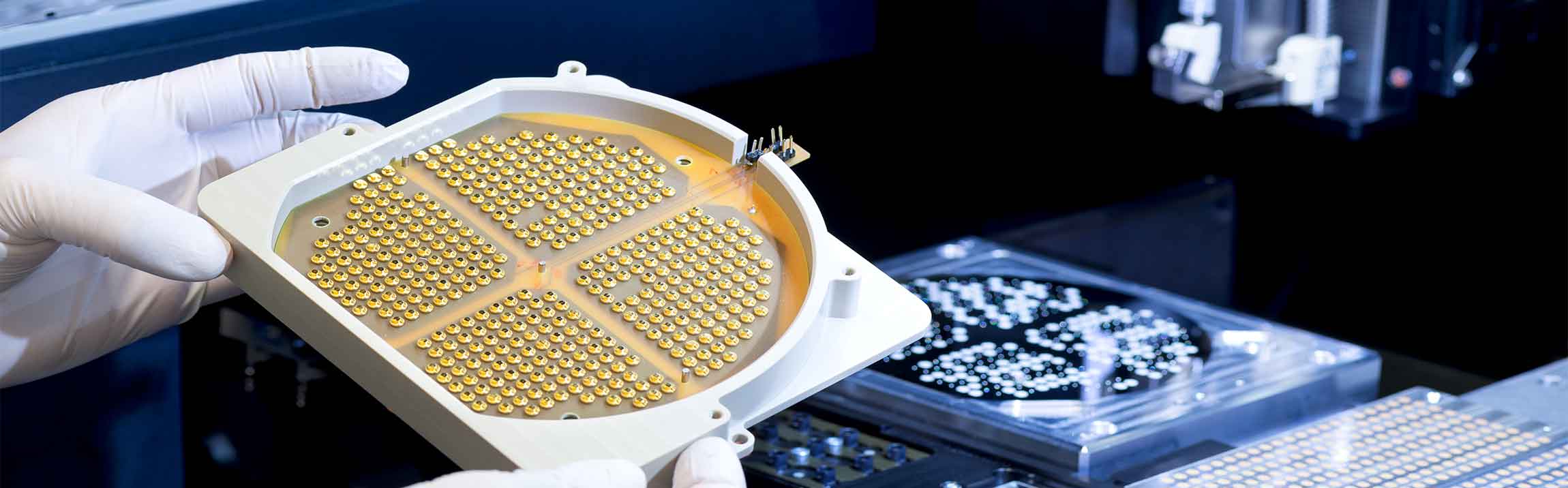

Design and Development of Micro Dosing Systems

Our customers can benefit from our expertise in the design of micro dosing systems and micropumps in joint collaborations. For example, customized micropumps are designed on the basis of users' specification requirements, whereby operating conditions, environmental influences, disturbance variables, manufacturing tolerances and material parameter variations can be taken into account. After manufacture researchers verify the design and additionally compare it to the achieved quality and reliability values.

Are you looking for precise, miniaturised dosing solutions for challenging fluid applications? Our micropumps and microdosing systems provide maximum accuracy and a compact design with intelligent control, making them ideal for use in medical technology, diagnostics, environmental analysis and many other areas.

In close collaboration with Fraunhofer EMFT and our interdisciplinary development team, we can provide a wide range of partnership opportunities:

- Contract development of customised solutions

- Consultancy services, technology transfer and integration of the latest research

- IP licensing of innovative technologies

- Participation in national and international funding projects.