Fraunhofer EMFT researchers have 30 years experience with dealing with all aspects of electrostatic discharge ESD in microelectronics - from the scientific point of view as well as in concrete industrial applications. Therefore, industry partners from all over the world rely on the competence of our experts for efficient solutions to acute problems, qualification of components with special requirements, and development of reliable ESD protection concepts for integrated electronic circuits and systems SEED. Fraunhofer EMFT is member of the German ESD-FORUM e.V. and the standardization committees for ESD-Test in the ESD Association.

Electrostatic Discharge - ESD

We encounter electrostatic discharges in everyday life more often than we would like - sometimes a seemingly harmless touch on a door handle is enough to feel the unpleasant discharges. Compared to electronic systems and technologies, however, humans react very insensitively, because even a low voltage can quickly trigger minor to serious damage, especially in high-speed technologies. This problem is exacerbated by the continuing trend towards miniaturization in microelectronics, which at the same time leads to a reduction in the maximum permissible discharge voltage. Improved ESD protection is therefore absolutely essential, especially in the environment of automated production. Load models are used to test individual components for their ESD resistance. However, common test methods are already reaching their limits in terms of accuracy and reproducibility, so that more precise measurement methods are becoming necessary.

Extensive test and measurement capabilities

For assessment and improvement of the robustness as well as the reproduction of failures, various methods for ESD testing (HBM, CDM, CC-TLP, 2Pin-Test, IEC 61000-4-2) and characterization (VF-TLP, TLP und Solid State Pulser) are applied and developed further. Examples for the latter include VF-TLP, CC-TLP and the modular CDM-Tester M-CDM3, also capable of measurements of potential distributions. Comparative physical analyses of failure signatures complement these capabilities.

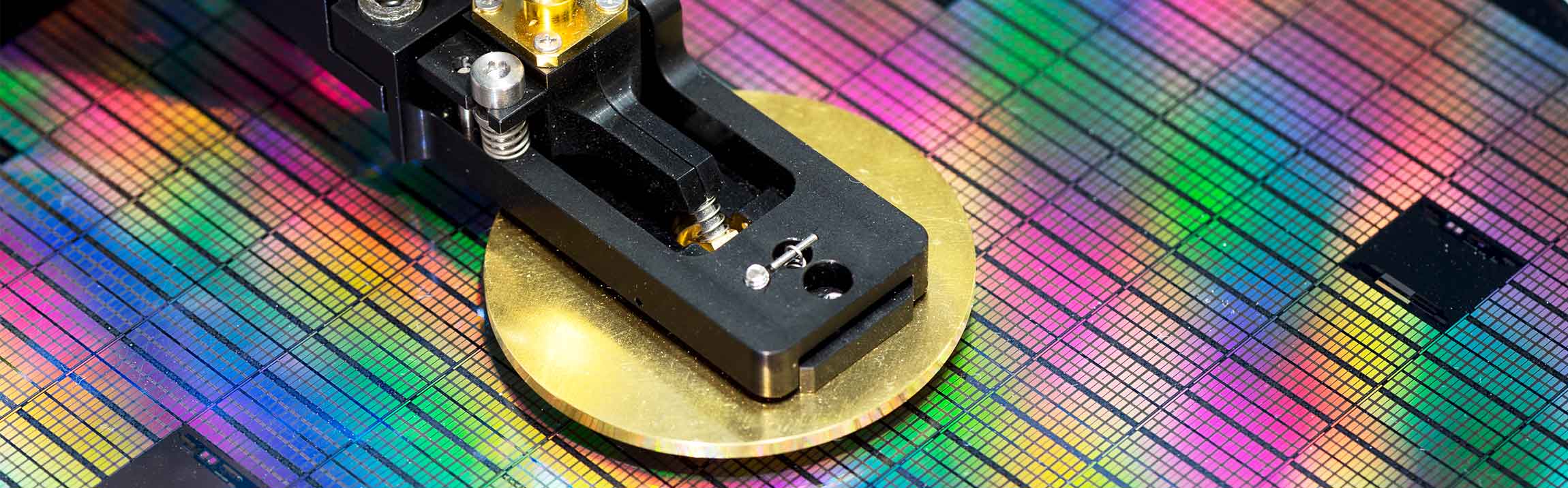

A 3D portal scanner is available for determination of the functional robustness of a 30 cm component against coupled and directly injected inteference signals, as well as its radiation characteristics.

CC-TLP as new standard for ESD testing

With the so-called Capacitive Coupled Transmission Line Pulsing (CC-TLP), the researchers have developed and patented a measurement technique that exhibits significantly higher accuracy and reproducibility in component testing than the commonly used CDM (Charged Device Model) test. This is especially important for highly miniaturized devices with very low ESD tolerance.

At system level, the experts at Fraunhofer EMFT specialize in detecting design-related interference effects as well as developing suitable protection concepts. The ability to test circuits directly on a wafer is also particularly useful, so that weaknesses in ESD protection can be identified at an early stage.

In October 2022, CC-TLP was published as a standard for ESD testing under ANSI/ESD SP5.3.4-2022.

Characterization of ESD protection structures

On behalf of various industrial customers, Fraunhofer EMFT researchers are characterizing ESD protection structures with high-current pulses transiently and quasi-statically in the automotive temperature range. Based on the analysis results, the experts develop high-performance protection concepts for different applications and requirements.

For the work, a modern fully equipped HPPI3011C TLP system in conjunction with a 300 mm Cascade PA300 or the new HPPI ATS_8000A Flying Probe System in conjunction with the Agilent 62 GHz Single Shot Oscilloscope DSOX96204Q are used. For industrial partners from the automotive and LED lighting sectors, among others, ESD/ EOS-induced failure scenarios are reproducibly simulated, loads are metrologically recorded down to the picosecond range, and their robustness is systematically increased.

Industry cooperation

The Fraunhofer EMFT team has received the 2016 Educational Research Council Grant from the American ESD Association Inc. to promote outstanding industry-relevant research in the field of electrostatic discharge. Specifically, the award funded a doctoral thesis investigating the correlation of the Capacitively Transmission Line Pulsing method CC-TLP developed at Fraunhofer EMFT against the Charged Device Model Test CDM, which is characterized by considerable measurement uncertainty. State-of-the-art integrated circuits with Gbit/s data rates were tested.