Press briefing: OQC and Fraunhofer EMFT Partner to Strengthen Quantum Fabrication Capabilities / 2025

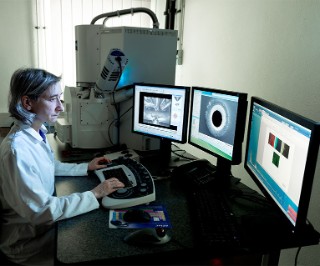

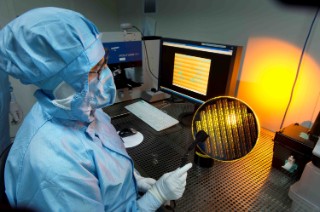

Collaboration for scalable manufacturing of superconducting quantum hardware

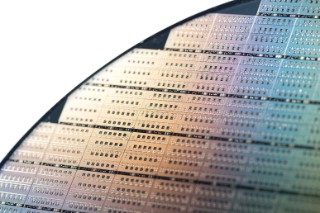

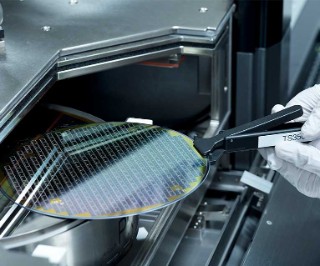

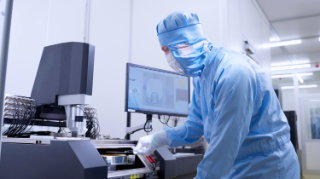

Oxford, 05 November 2025 – Oxford Quantum Circuits (OQC) and the Fraunhofer Institute for Electronic Microsystems and Solid State Technologies EMFT today announced a strategic partnership designed to accelerate the industrialisation of superconducting quantum technologies. By merging OQC’s system-level quantum expertise with Fraunhofer’s advanced fabrication capabilities, the partnership charts a new course towards scalable, manufacturable quantum computing. The collaboration represents a pivotal step in OQC’s journey towards fabless production, aligning superconducting quantum devices with industry-standard, CMOS-compatible processes that underpin global semiconductor manufacturing.

more info