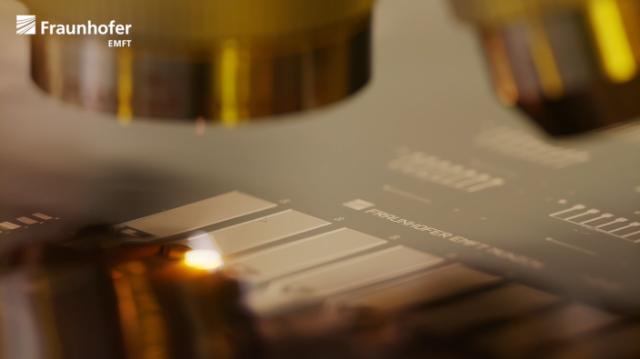

Roll to roll process of flexible substrates enables the production of novel electronic systems that meet challenges regarding more freedom in design and shaping. Thus, this manufacturing technology enables new fields of application where the future electronic systems need to be thin, pliable and flexible.

Roll to roll process of flexible substrates

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyRoll to Roll Flexible Electronics

Flexible electronics creates entirely new possibilities in terms of form factors, which in turn ultimately set the course for truly innovative and flexible product design. The Fraunhofer EMFT pilot line with roll-to-roll lithography, laser structuring, printing, vacuum-based techniques and system integration enables cost-effective processing for the development of electronic systems that are simultaneously thin, flexible and large-area.

Using a direct-write lithography system alongside digital stitching techniques enables the fabrication of conductive tracks over lengths of several metres, allowing for the production of "endless" flexible electronics. This advancement makes it possible to create large-scale, flexible circuit carriers with strong potential applications in medical devices, energy systems, automotive components and large-area LED lighting surfaces. These continuous, flexible electronics open up new possibilities for integration into curved, dynamic or space-constrained environments. The practical implementation of these technologies in roll-to-roll manufacturing and system integration has previously been demonstrated in projects such as HyperStripes.