Fraunhofer EMFT has been a leader in the research and application of electrostatic discharge (ESD) in microelectronics for over 30 years. Our expertise spans from resolving acute technical challenges and qualifying components with special requirements to developing robust ESD protection concepts for electronic circuits and systems. As an active member of the German ESD Forum e.V. and the ESD Association’s standards committees, we are internationally recognized for our contributions to the field. Our laboratory uses both standardized and in-house developed methods and systems for ESD testing. A particular focus lies in the development of customized ESD test equipment – especially for CDM and CC-TLP test methods. In close collaboration with our partners, we deliver complete, practice-oriented system solutions that integrate seamlessly into existing development and quality assurance processes.

ESD - Electrostatic Discharge

We often encounter electrostatic discharges in everyday life more often than we would like - sometimes all it takes is touching a door handle to feel the unpleasant discharges. Compared to electronic systems and technologies, however, humans are very insensitive to electrostatic discharge, as even a low voltage can quickly lead to damage, especially with high-speed technologies. This problem is exacerbated by the ongoing trend towards miniaturization in microelectronics, which also leads to a reduction in the maximum permissible discharge voltage. Adequate ESD protection is therefore essential, especially in automated production environments. Individual components are tested for their ESD resistance using standardized load models. However, conventional test methods are already reaching their limits in terms of accuracy and reproducibility, meaning that more precise measurement methods are required.

Characterization of ESD protective structures

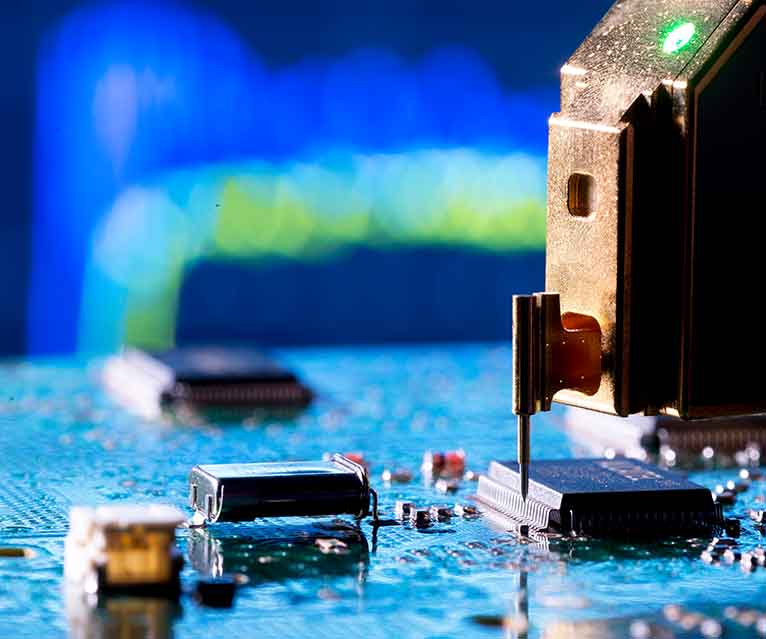

On behalf of various industrial customers, researchers at Fraunhofer EMFT characterize ESD protection structures in the ESD-relevant high-current range and with a transient resolution of a few tens of picoseconds. Based on the analysis results, the experts develop high-performance protection concepts for different applications and requirements.

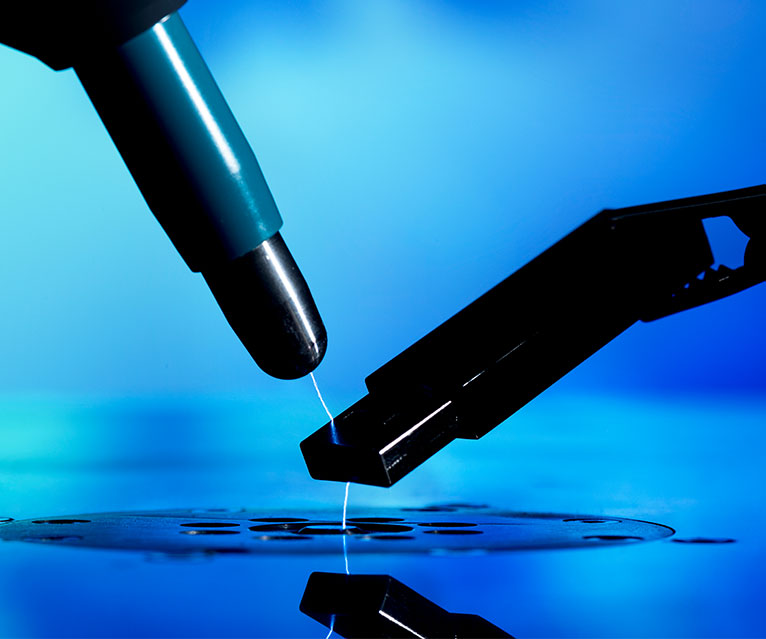

A modern, fully equipped HPPI3011C TLP system in conjunction with a 300 mm Cascade PA300 or the HPPI ATS_8000A Flying Probe System in conjunction with broadband oscilloscopes (>33 GHz) from Keysight are used for the work.

ESD/ EOS-induced failure scenarios are reproducibly simulated for industrial partners from the automotive and LED lighting sectors, among others, and loads are measured down to the picosecond.

At the system level, the experts at Fraunhofer EMFT specialize in detecting design-induced disturbances and developing appropriate protection concepts.

CC-TLP as new standard for ESD testing

With so-called Capacitively Coupled Transmission Line Pulsing (CC-TLP), the researchers have developed and patented a new type of measurement technology that offers significantly higher accuracy and reproducibility in component testing than the commonly used CDM (Charged Device Model) test. This is particularly important for modern technologies with low ESD tolerance. The ability to test circuits directly on a wafer is also particularly useful, allowing weaknesses in ESD protection to be detected at an early stage.

In October 2022, CC-TLP was published as a standardized procedure for ESD tests under ANSI/ESD SP5.3.4-2022.

ESD Testing and Qualification for Industrial Applications

Our services are aimed at companies looking to establish in-house ESD test methods or optimize existing processes – with solutions precisely tailored to their technologies and products. Our service portfolio includes:

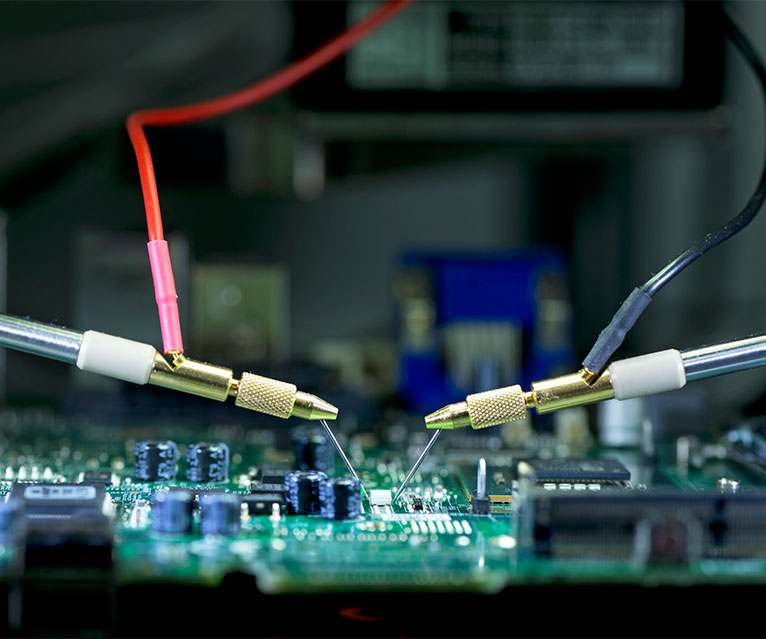

- ESD Human Body Model (HBM) test according to ANSI/ESDA/JEDEC JS-001-2023 at wafer/die/package level (2-pin HBM tester)

- ESD Charged Device Model (CDM) test according to ANSI/ESDA/JEDEC JS-002-2025

- ESD high current characterization with Transmission Line Pulsing (TLP) on wafer/die/package level with impulse lengths of sub ns to µs domain at various rise times (ANSI/ESD STM5.5.1-2016)

- Capacitively Coupled TLP (CC-TLP) for evaluating CDM stability with significantly higher precision and reproducibility (ESDA Standard Practice Document published as ANSI/ESD SP5.3.4-2022)

- Human Metal Model (HMM) measurements according to ESD SP5.6-2019

- System-level ESD analyses derived from IEC 61000-4-2

- Loading of circuits in standard enclosures, but also of special enclosures up to bare dies

A key benefit for our customers: Upon request, we develop complete, turnkey ESD test systems – for CDM or CC-TLP – that integrate seamlessly into existing development and quality assurance processes. This enables companies to perform ESD testing independently, efficiently, and in full compliance with industry standards.

In close collaboration with partners such as High Power Pulse Instruments GmbH, these solutions are transformed into market-ready systems that are already being successfully distributed and used in industrial applications.

Electromagnetic Compatibility (EMC) Analysis and Measurements

- Scanner measurements of the radiation of products at board level

- Measurement of the sensitivity of systems to interference (conducted or non-conducted)

Customised and modular test systems

In addition to standardised ESD tests, Fraunhofer EMFT develops customised electrical test equipment tailored to specific requirements. The M-CDM3 modular ESD test system offers a high degree of flexibility and can be expanded in many ways, even beyond classic ESD tests.

Your advantages at a glance:

- Modular design: Customisable hardware and software components for different test requirements

- Individual expandability: Implementation of additional electrical test functions beyond ESD

- High precision: Positioning accuracy in the micrometer range for demanding layouts

- Flexible test planning: Freely definable charging and discharging sequences, adaptable to complex pin layouts

- Integration & service: Support for CE-compliant system integration and comprehensive maintenance service