The ongoing miniaturization in the microelectronics and semiconductor technologies has significantly increased the requirements on electronic components and systems. Due to the complexity and variety of possible fault mechanisms, failures and malfunctions can cause serious challenges especially for SMEs. Based Against this backdrop, Fraunhofer EMFT scientists use their many years of scientific experience and expertise in the field of damage or fault analysis, quality assurance and process consulting.

Reliability and Failure Analysis of Electronic Components

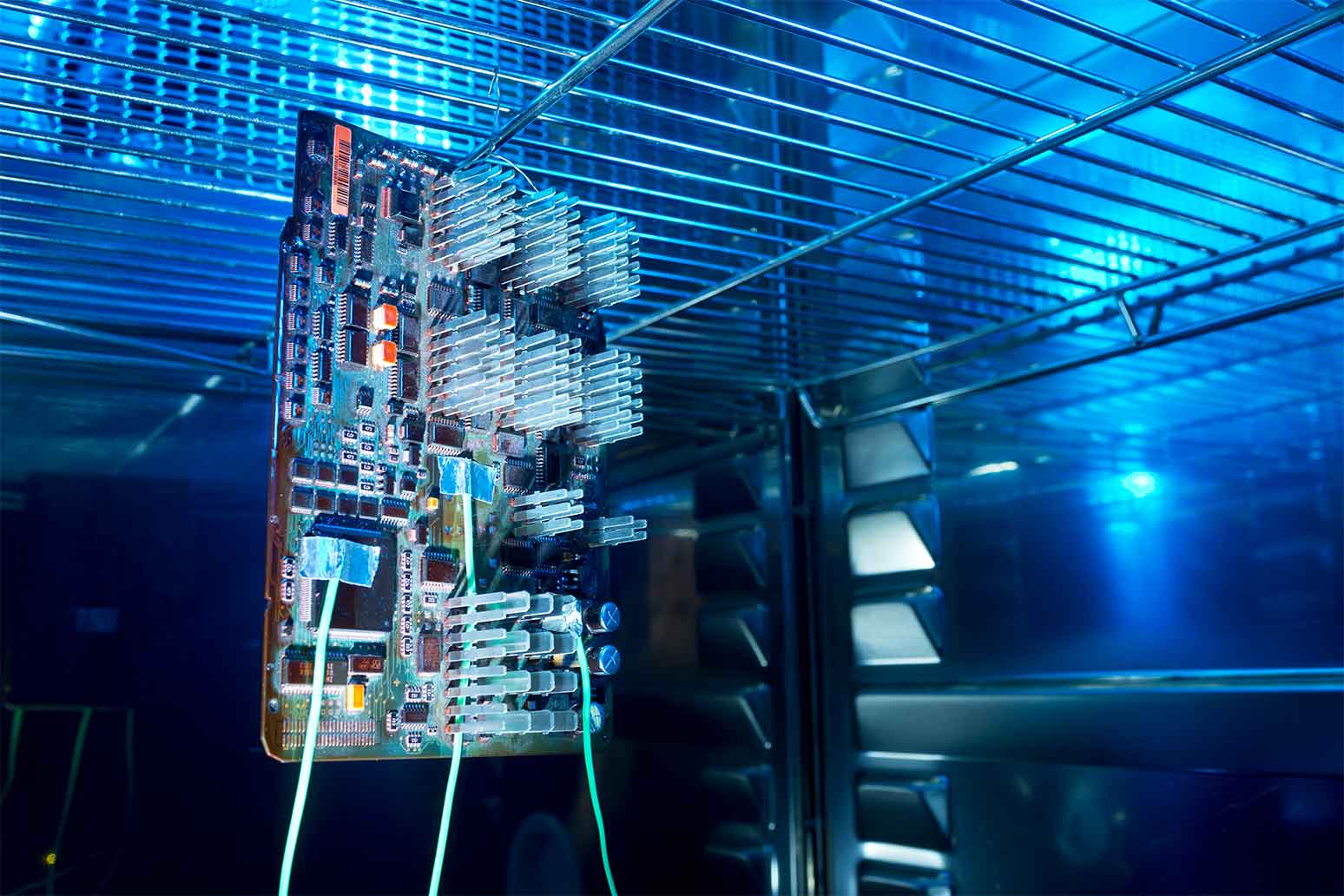

Failure analysis for SMD components, printed circuit boards (PCBs) and integrated circuits (ICs)

Based on our technological understanding in combination with state-of-the-art measurement and analysis capabilities, extensive multiparametric characterizations and qualification tests of electronic components and systems can be performed. This allows for physical influencing variables to be simulated under laboratory conditions and the reaction of the component to the respective parameter to be determined both individually and as a collective. Using suitable stress tests and environmental simulations, manufacturing defects and relevant weak points can be addressed, and an estimate of the reliability and service life of modules and components can be made. Through systematic analysis, product and process optimization can be derived accordingly. In addition, we can support you with non-destructive and destructive investigations in the quality assurance of your manufacturing processes.

The Fraunhofer EMFT analyses cover a wide range of the following standards in the electronics industry:

- IPC standards: Our qualification and reliability testing is performed in accordance with IPC standards, including IPC J-STD-001, IPC-A-610, IPC-6012, IPC-6013, and IPC-A-600, ensuring that your assemblies and PCBs meet the highest quality standards.

- ESA Standards: As an approved ESA qualification laboratory, we perform examinations in accordance with the requirements of the European Space Agency (ESA). Our qualification tests for ESA projects ensure the reliability and quality of your electronic components for use in space.

- DIN standards: We also consider the relevant DIN standards to ensure that your products comply with German national standards. These include, for example, DIN EN standards for solderability of components and printed circuit boards.

Our goal is to provide you with a reliable and accurate evaluation of your products in accordance with the relevant standards. We support you in your R&D activities for achieving the highest quality standards and meeting the requirements of your industry.

Overview of the Analytics and Material Testing

The Fraunhofer EMFT expertise covers a wide spectrum of requirements, based on delivery specifications and acceptance criteria as well as international standards from various industries, such as aerospace (ESA), automotive incl. suppliers, medical technology or industrial electronics.

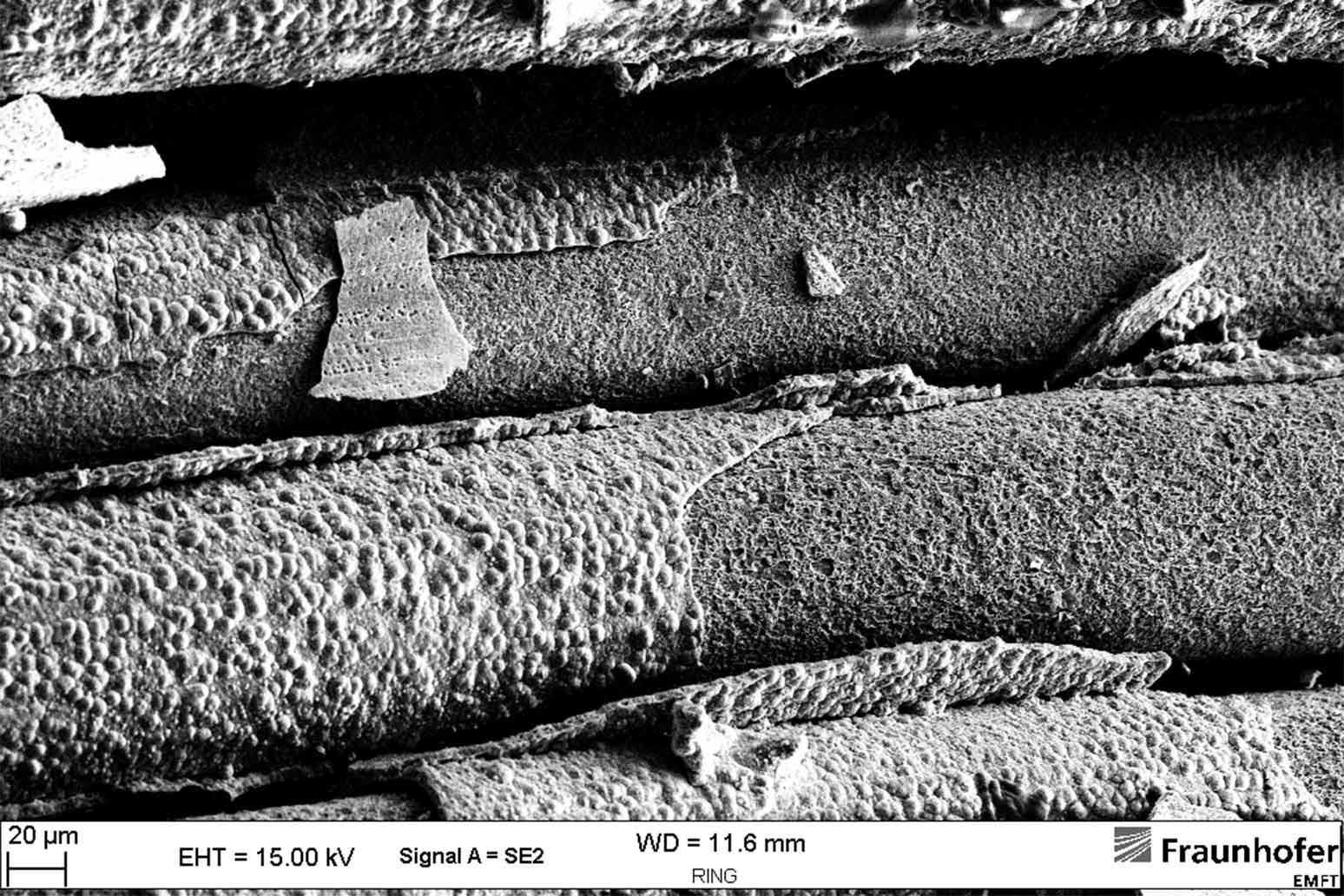

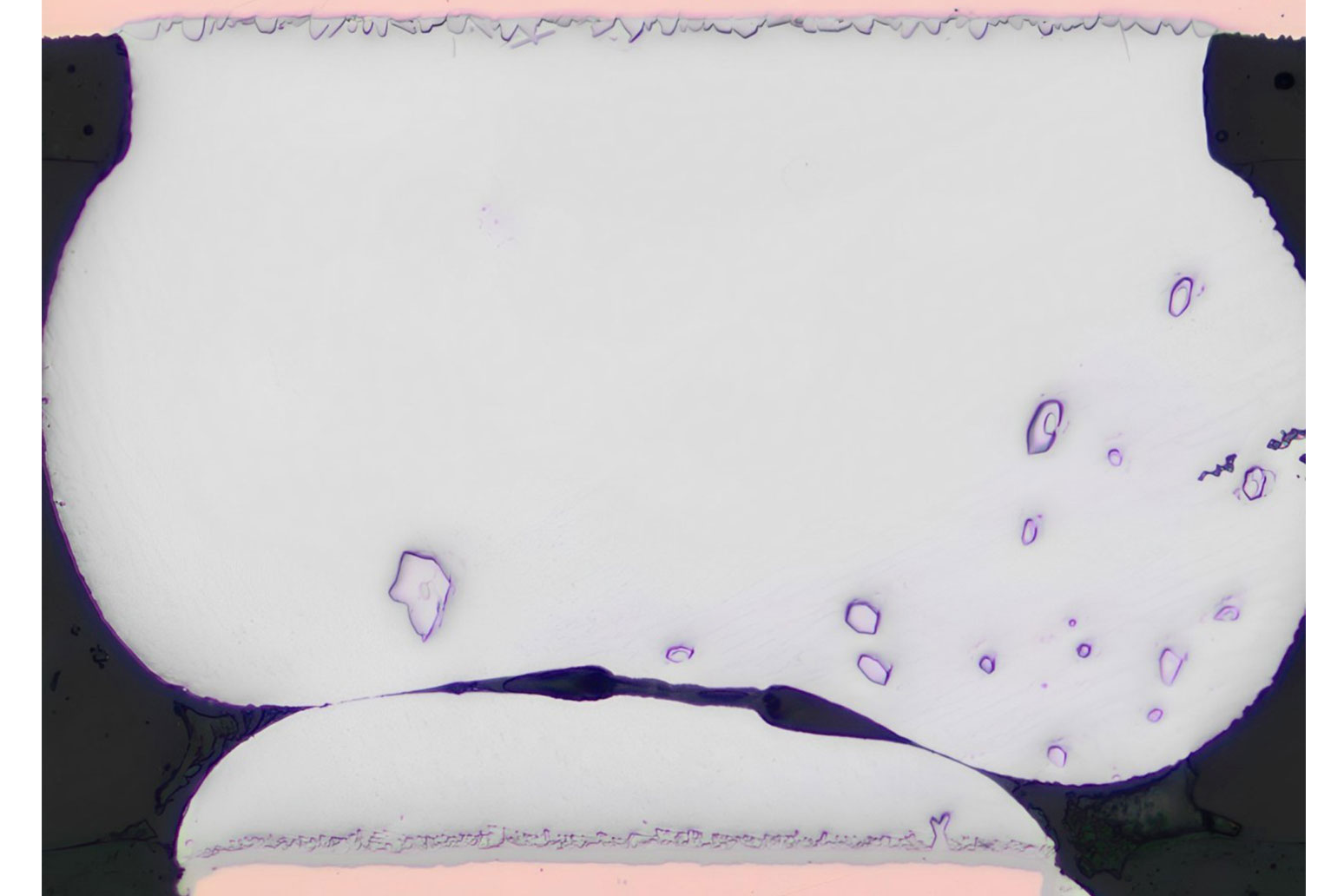

- Analysis by means of light-optical and X-ray inspection, metallographic microsection preparation and scanning electron microscope

- Qualification tests and reliability tests of printed circuit boards, electronic assemblies and auxiliary equipment

- Assessment according to IPC; ESA or DIN

- Qualification testing for ESA projects - ESA-Accepted Qualification Lab

- Risk analysis and process optimization as well as development of test methods and equipment

- Damage analysis

- Reverse Engineering

Qualification and Reliability Tests

- Inspection of electronic assemblies according to IPC-J-STD-001 and IPC-A-610

- Solder Joint inspection according to IPC-J-STD-001 und IPC-A-610

- Printed circuit board inspection according to IPC-6012 (Rigid), IPC-6013 (Flex); IPC-6015 (MCM-L) and IPC-A-600

- Solderability tests for electronic assemblies and PCB according to DIN EN or IPC

- Contamination Tests on PCB and electronic assemblies

- Qualifications for solder-free connection techniques such as crimp connections; pressfit technology, plug connectors

- Qualifications for electrical connectors (crimp connections, pressfit technology, plug connectors)

- Crimp inspection (Voltage Drop; Tensile testing; Durability)

- X-ray inspection with high-resolution CT as well as laminography and in-situ measurements

- Active thermography

- Structural analysis and materials characterization

- Surface Characterization: Roughness measurement, topography, Coating thickness

- Corrosion analysis

- Vibration and Shock Environmental Test

- Tensile, compression and flexure tests with climatic chamber and video analyses

- Environmental simulation and reliability tests

- Cyclic temperature-humidity test to +95°C und 98 % r.F

- Temperature cycling test to +200°C and 10 k/min

- Rapid temperature change tests to -80°C and 220°C

- Heat Storage to +300°C

- Active power load tests

- HAST (highly accelerated stress test)

- Condensation tests with isolation resistance measurement

- Combination of electrical/mechanical inspection and measurement tools