The field of Artificial Intelligence (AI) has made immense progress in recent years and plays a crucial role in dealing with complex tasks with temporal data structures. AI algorithms for time series analysis provide special methods and models that aim to recognize patterns, trends and structures in temporally ordered data sets in order to detect anomalies and defined states or to make precise predictions for future values. These algorithms use advanced mathematical models and machine learning to capture complex relationships between past, present and future points in time in the data. The purpose is to gain insights into the temporal development of data, generate predictions for future values and support decision-makers in various areas such as healthcare and production. The application of AI algorithms in time series analysis thus enables a more precise and effective use of temporal data trends for strategic planning and decision-making.

AI Algorithms for Time Series Analysis

Decoding complex patterns and structures in data

The group Machine Learning Enhanced Sensor Systems (MLS) at Fraunhofer EMFT has extensive experience in data mining and the development of AI algorithms for time series. Data mining is data-driven knowledge discovery, i.e. finding relevant patterns and structures in the data, and includes both classical statistical methods and AI methods.

The basis of any analysis is the data. It is therefore crucial to understand the basic properties of time series data. Good data analysis and AI methods are tailored to the specific requirements of time series data. Based on the expertise and resources that the MLS team has built up in relation to AI algorithms for time series analysis, the group offers services ranging from feasibility studies and consulting to development of a full system.

Time Series Data

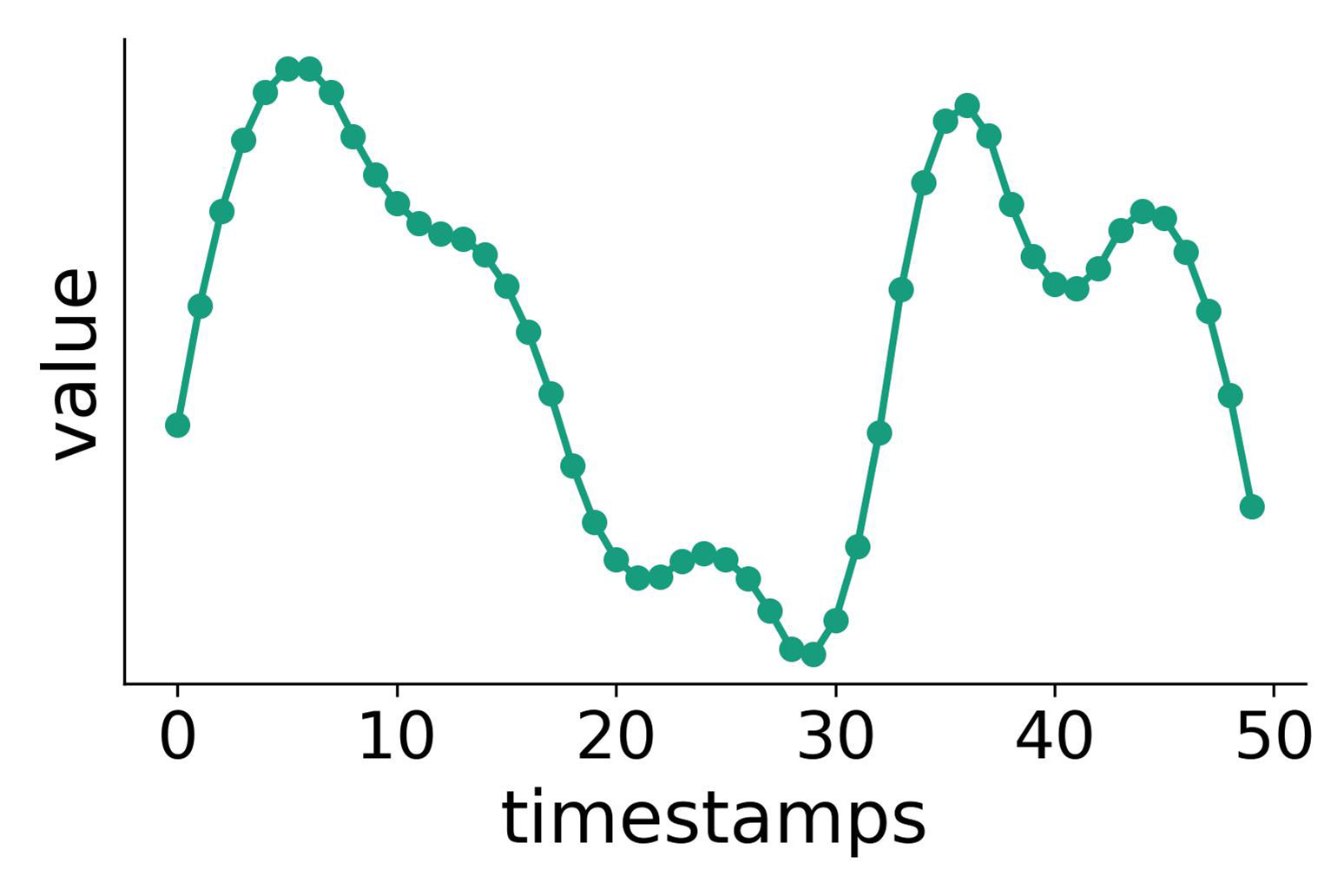

In the digital world, time series data is ubiquitous. Whether it comes from environmental sensors, industrial plants, vital sensors, stock markets or other sources does not change its inherent feature: the fixed order of the values that are each provided with a time stamp (see figure exemplary time series). Time series data exhibits some data type -specific challenges. In contrast to classic tabular data, time series data is not independently distributed. Often a significant auto-correlation is present.

In real life applications, large amounts of multivariant data are often collected in a very short time, which makes data analysis highly complex. In industrial plants, for example, time series data are collected from multiple sensors over years at a high sampling frequency. This can easily result in hundreds of millions of data points. Relevant features may be far apart in time, or they may be in close proximity. Consequently, a fitting machine learning model should be able to capture long-term system trends and far apart interrelationships, without compromising the local awareness.

Not only the structure of time series data is different in comparison to other datatypes, but also the patterns in the data. For example, periodic patterns are much more common in audio signals than in natural images. Another challenge for time series data mining are irregular sampling rates or rare events that are difficult to analyze or predict.

AI Methods

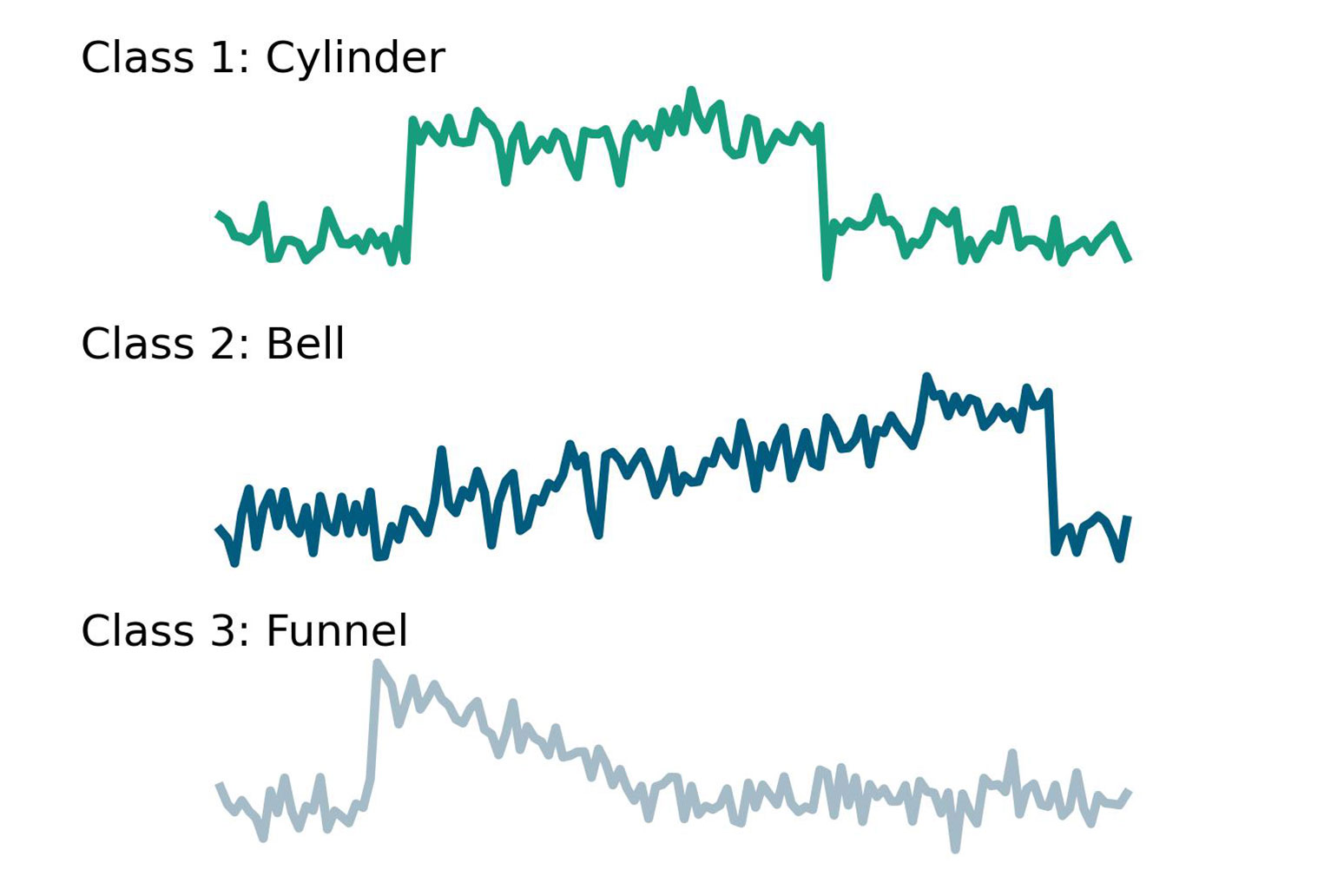

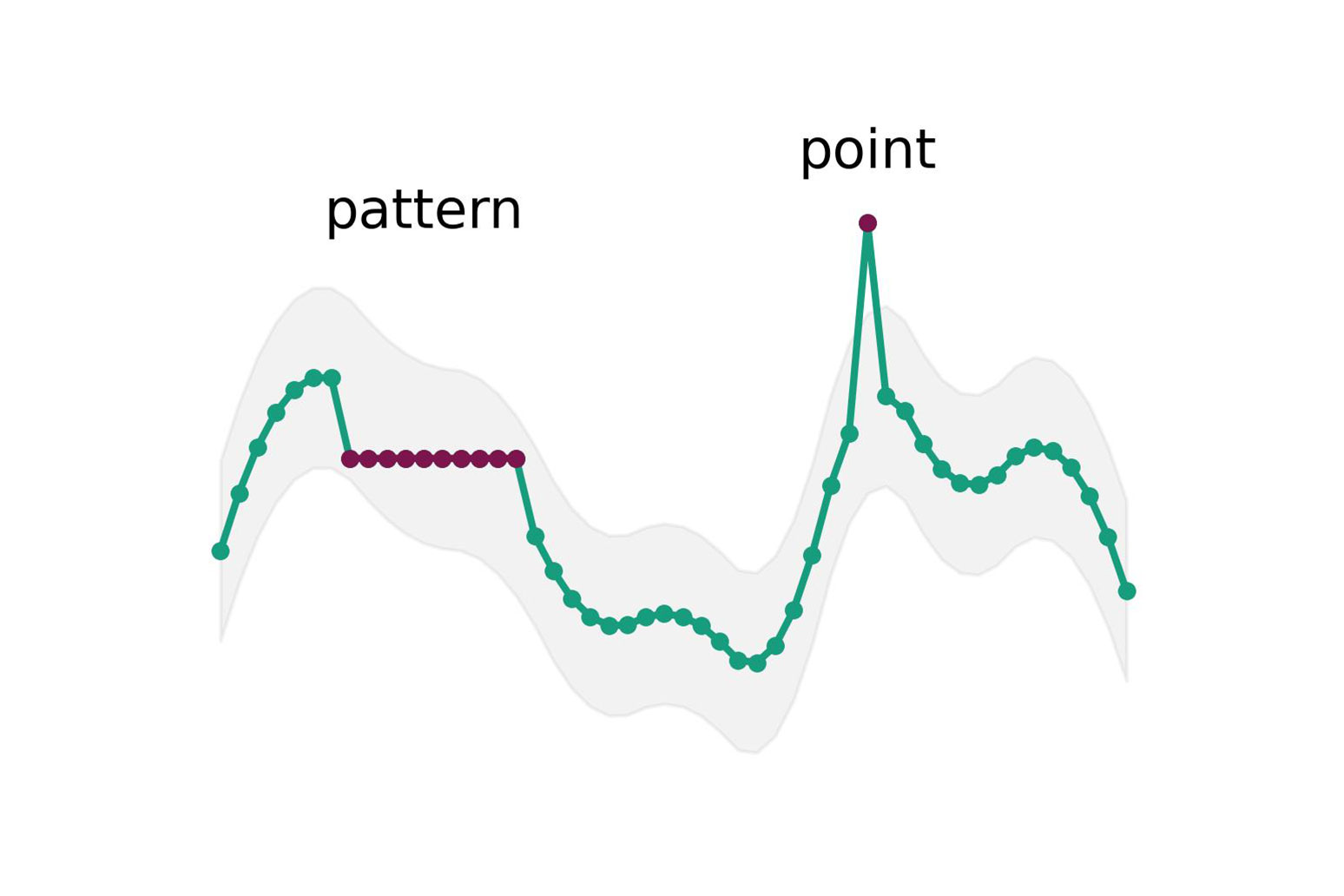

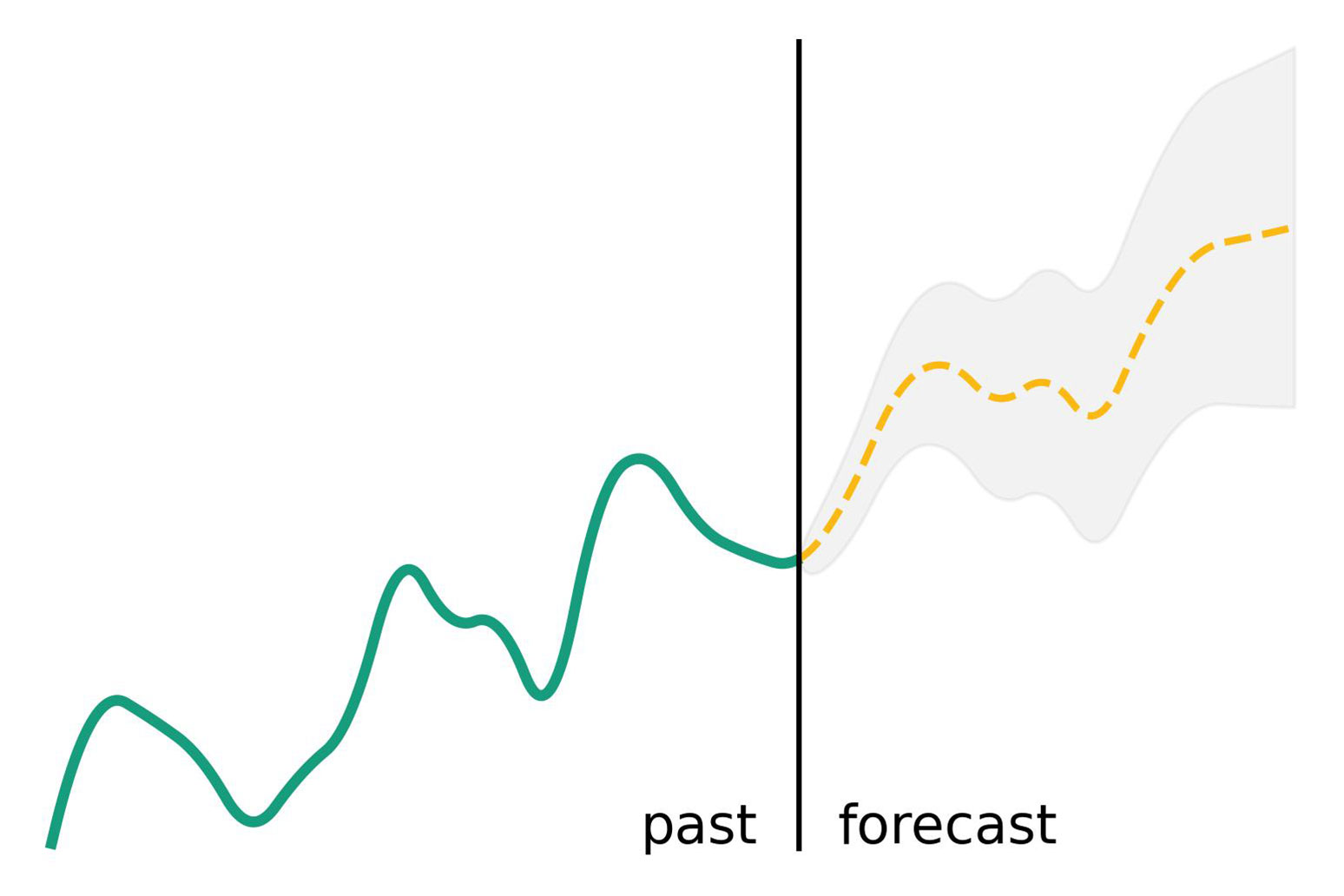

To extract knowledge from time series data, classical mathematical analysis methods can be used. For example, the Fourier analysis is a method in widespread use. Due to an increase of computing power, ever-growing amounts of data can be saved and processed. As an alternative to writing explicit software that defines mathematical rules to solve problems, machine learning can be employed for data-driven knowledge discovery. For tasks like regression (e.g. physical modeling), classification (see below fig. 1), anomaly detection (see below fig. 2) and forecasting (see below fig. 3) machine learning is the preferred method. Especially when these tasks are non-trivial to solve with classical methods or when classical methods are computationally too costly, machine learning is the state of the art. Depending on the difficulty of the problem, the model complexity ranges from simple linear models to complex deep neural network architectures.

In Time Series data mining, a good baseline is automatic feature extraction in combination with classic machine learning models. Another time series specific property is that relatively strong distance metrics for one dimensional data over time are available. This means that the similarity of two time series can be assessed relatively well using an Euclidean distance combined with dynamic time warping. Both in time series classification and in univariate anomaly detection this similarity measure proofed to be competitive. Another class of machine learning models is designed specifically for time series data. Some of these models limit the complexity of time series data by introducing a quantization or by down-sampling the data. With the same goal in mind, deep neural network architectures have also been adapted to meet the specific challenges of time series data. Famous examples of deep learning architectures adapted to time series data are Convolutional Neural Networks (CNNs), Recurrent Neural Networks (RNNs) or, more recently, the Transformer architectures.

Industrial Applications & Edge AI

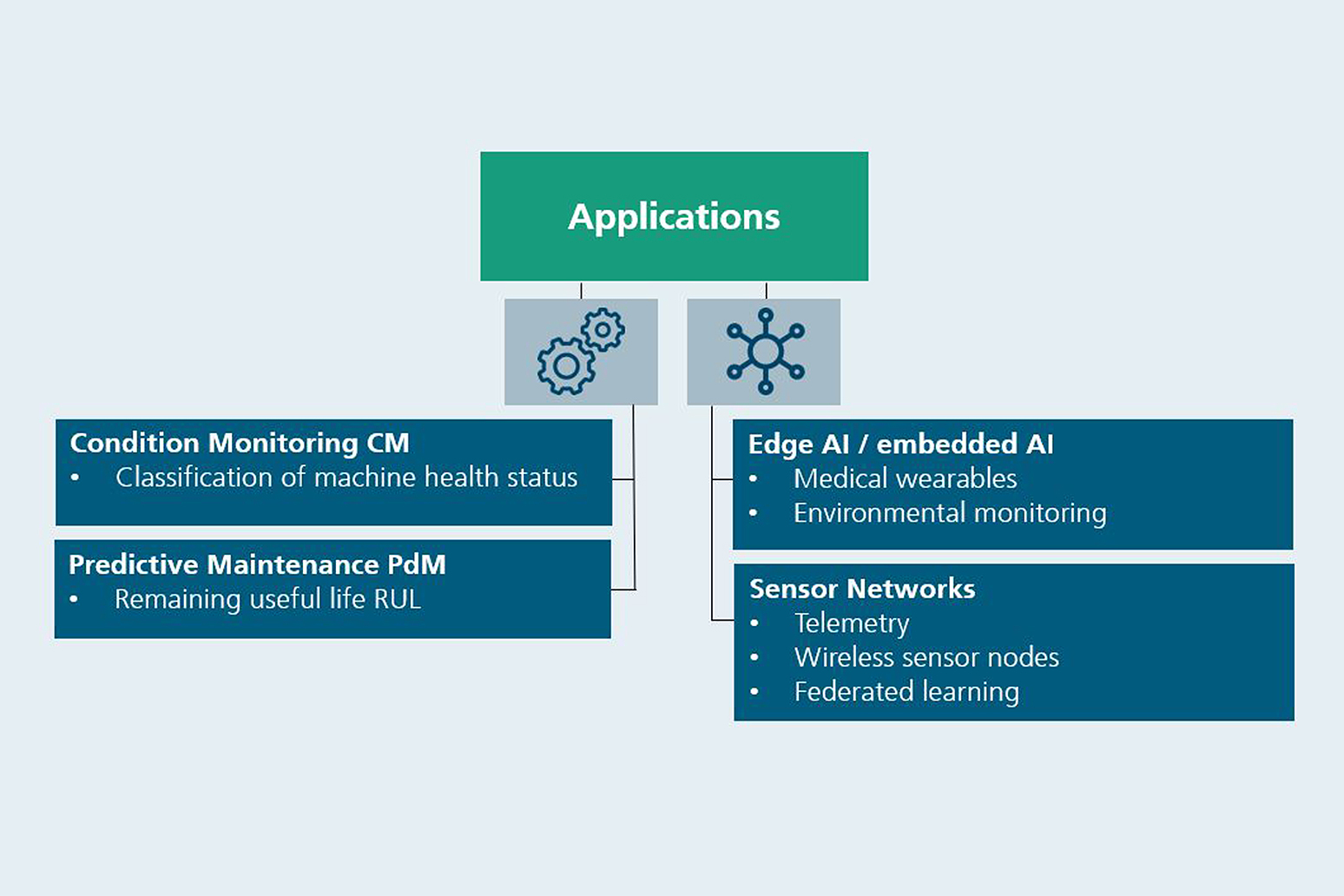

AI algorithms can be used in any business sector, where data is recorded over time. Examples are Industry 4.0 with IIoT, logistics, finance, electric grids, web traffic, environmental monitoring or healthcare data. The MLS Group has extensive experience in time series data mining through numerous research and industry projects. Especially in these application areas, projects have been successfully completed:

Time Series Analytics for Industrial Applications includes condition monitoring and predictive maintenance. The great challenge of this application is that huge amounts of data are collected from multiple different sensors and control devices on multiple machines or process steps. The first step is to identify the relevant patterns in the data to assess the condition of a machine or industrial plant – Condition Monitoring. Then, based on service history and past experience, the remaining useful life (RUL) can be predicted to enable Predictive Maintenance.

The second project focus is Edge AI. In a given network the edge is closer to the sensor while the server or the cloud is the centralized computing unit. Often edge devices are embedded devices on which machine learning is executed. The challenge of Edge AI is to deal with limited computing power. For a given use case, the embedded system and the machine learning software need to be co-designed. Since the data is aggregated on multiple independent edge devices, it is possible to enhance data privacy by the use of federated learning. In the federated learning scheme, only model updates are exchanged between edge devices and the cloud, while the raw data remains local.

[1] Saito, Naoki and Ronald R. Coifman. “Local feature extraction and its applications using a library of bases.” (1994).

Leverage our expert AI algorithms for time series analysis at Fraunhofer EMFT for your specific application needs. We are eager to collaborate and innovate with you - contact us!