Fraunhofer EMFT develops intelligent sensor systems and enhances their capabilities using machine learning methods. These 'machine learning-enhanced sensor systems' enable the creation of innovative sensor solutions that conserve energy, reduce bandwidth usage, shorten response times, and securely manage sensitive sensor data.

Machine Learning Enhanced Sensor Systems (MLS)

Intelligent sensor systems thanks to machine learning

Sensor Systems

At Fraunhofer EMFT's MLS (Machine Learning Enhanced Sensor Systems) group, we develop intelligent sensor systems that integrate both our proprietary sensors and commercially available physical sensors. Our expertise focuses on designing sensor circuits using microcontrollers, as well as programming embedded software and firmware.

These developments include the analogue front end, the subsequent conversion of the analogue signals using an analogue-to-digital converter, digital processing in the microcontroller and various wired (USB, RS232, RS485, OPC UA, CAN, Ethernet...) and wireless interface technologies (BLE - Bluetooth Low Energy, 868MHz solutions, WLAN, NB-IoT...).

One area of Machine Learning Enhanced Sensor Systems focuses on complex optical analysis systems that are based on optical principles such as absorption, chemiluminescence or fluorescence at different wavelengths or the recording of a spectrum. This allows material analysis and the recognition of surface properties, as well as biological substances in agricultural and medical applications. In particular, spectral analysis in the visible (VIS) and infrared (IR) ranges offers comprehensive information for a wide range of applications.

In addition to optical sensor systems, the Fraunhofer EMFT also develops and investigates sensor systems for vibration measurement, the recording of environmental parameters such as temperature, humidity, UV radiation, CO2 concentration, as well as gas sensors for various analytes, and more.

The fields of application for the sensor systems of the MLS group range from Internet of Things (IoT) devices and Industrial Internet of Things (IIoT) devices for industrial applications to wearable devices and fixed installed sensor systems used in Industry 4.0 scenarios.

Machine Learning

Machine Learning is a field of Artificial Intelligence (AI) that learns by training statistical models from training data. This enables the automatic detection of patterns and regularities in the training data, which can also be applied to new, previously unknown data from the same process. The transfer of learned knowledge to unknown data is also referred to as generalization and is assessed during evaluation using a test dataset. Machine Learning can be used, for example, to detect anomalies, classify states, and predict future behavior. Probabilistic Machine Learning models also provide the ability to indicate the uncertainty of model predictions.

In the area of sensor technology and sensor systems, the Fraunhofer EMFT utilizes Machine Learning to process the collected sensor data, which is typically in the form of a time series. Within this context, unsupervised and semi-supervised approaches are employed for anomaly detection, as well as supervised approaches for classification and pattern recognition, in order to assign the data to a specific state. Based on these methods, intelligent sensor systems combined with Machine Learning are employed in production technology for Condition Monitoring (CdM) and Predictive Maintenance (PdM).

One example is predictive maintenance of gear oils, where Machine Learning models can be used to predict the need for maintenance before a failure occurs. This reduces expensive routine maintenance to only when it is actually needed.

Data Processing at the Edge

The use of Machine Learning directly in the microcontroller of sensor nodes paves the way for promising new solutions. The so-called Edge AI or Embedded AI enables local processing on the sensor node. By using local inference of ML models on the sensor node, conclusions can be drawn that can trigger further actions. This saves energy and time, as the raw data does not need to be sent to the cloud for evaluation. This is particularly interesting in areas where sensitive data is being used, such as medical technology or secure environments. Here, the sensitive data does not need to be sent at all, which increases data security by avoiding potential risks during transmission. Even time-critical applications, such as hazard detection in future autonomous driving, can be performed directly on the sensor node, which would not be possible with cloud-based processing. However, an ML model present in the sensor node must be secured against theft or manipulation. This is of crucial importance. Suitable security measures must be implemented to guaranteee the integrity and confidentiality of the model. An additional advantage lies in the more efficient IT infrastructure, which does not need to be expanded to ensure the transmission of raw data.

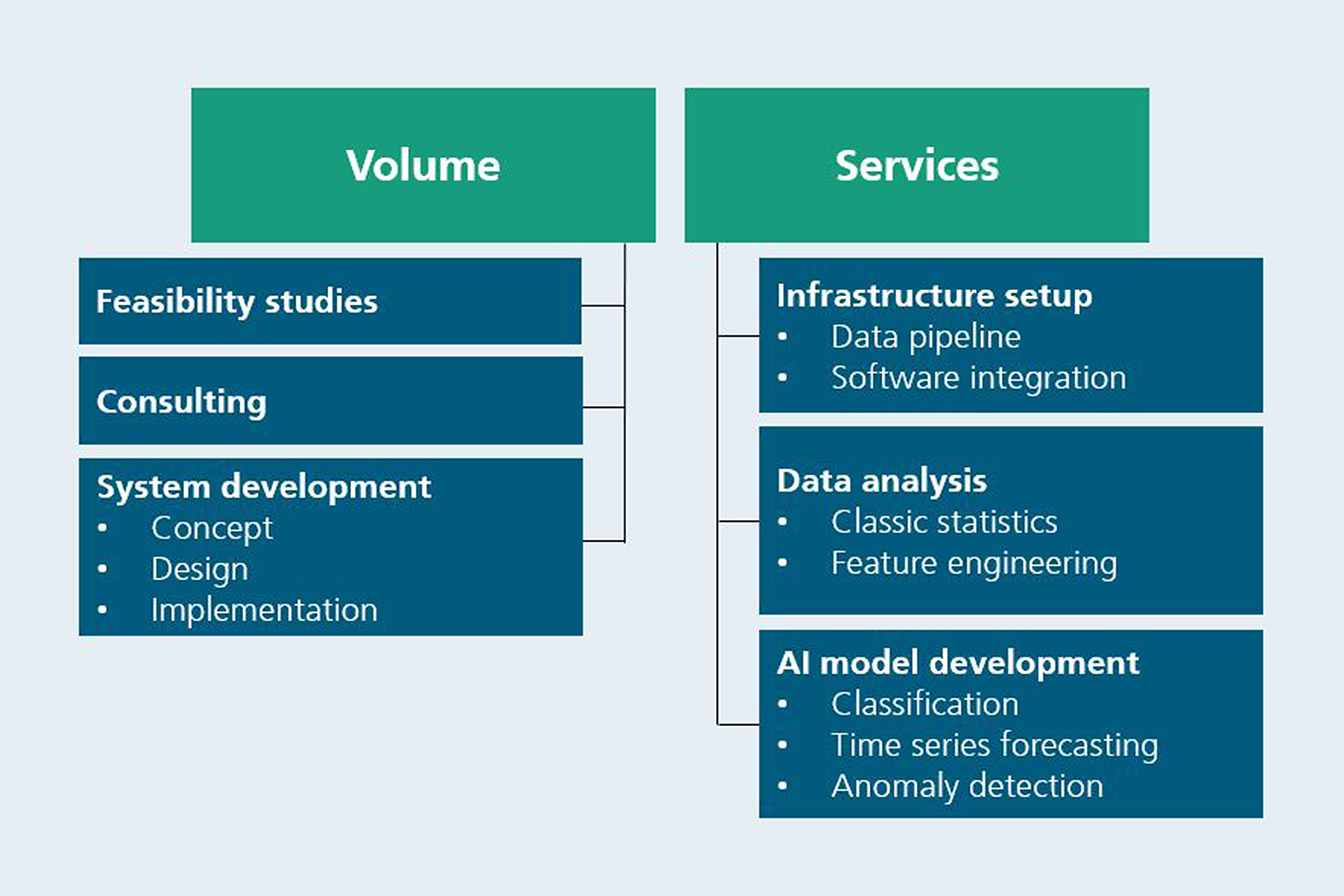

Offerings

The Fraunhofer EMFT group MLS offers a comprehensive data mining service to unlock the potential of your time series data. The range of services starts with small feasibility studies to evaluate the potential of a Data Mining solution, but also accompanies the entire engineering of the data mining system. This includes system conception and component design, both hardware and software, as well as the implementation and evaluation of the overall system.

Typically, a large percentage of the workload is not spent directly on developing machine learning models, but on setting up a suitable infrastructure. The setup must combine the data pipeline, consisting of data acquisition, pre-processing and storage, with the software integration, to build, test and deploy machine learning models.

The data analysis services range from classical statistics to dedicated Model development for regression, classification, forecasting or anomaly detection.

Expertise and Resources

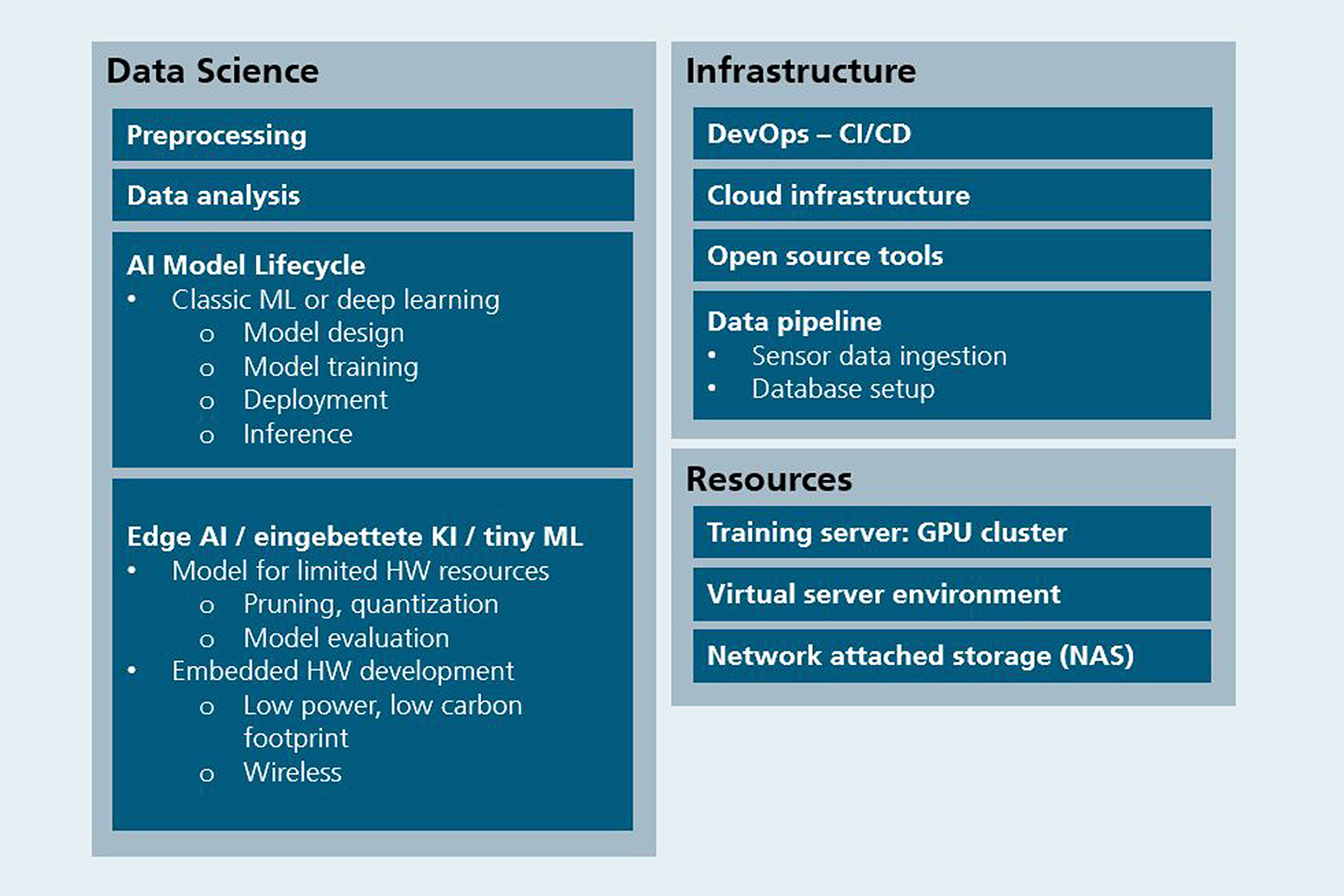

Through several completed research and industry projects the MLS Group has built up experiences and resources that a client can benefit from. As a data science project often consists of the same steps, the group has aggregated references for each step. This includes both the infrastructure setup and the actual data science pipeline.

The available hardware resources are a key success factor. The MLS group has a high-performance training server (NVIDIA GPU cluster) and a virtual server environment with network-attached storage (NAS). All requirements for an in-house analysis of client’s data are in place. This means that the clients data is not exposed to the outside world.