Diabetes types that require regular insulin treatment are highly dependent on the patients' ability to constantly track their blood glucose levels and self-administer insulin accordingly. This not only causes a major inconvenience in everyday life, but also involves the risk of hyperglycaemia or hypoglycaemia. In addition, in certain situations a blood sugar deficiency can only be predicted inadequately. Together with five European partners, the researchers at Fraunhofer EMFT are developing an implantable measuring and dosing system. It is capable of monitoring all relevant key metabolic parameters on a situation-specific basis and adjusting the insulin dosage accordingly.

Three-metabolite measurement device for safe and convenient diabetes management

Project MuSIC4Diabetes

Diabetes mellitus is on the rise globally. The number of cases has increased dramatically over the last three decades and experts estimate that there will be around 629 million cases worldwide by 2045. The treatments currently available for diabetes not only affect patients in their everyday lives, but are also vulnerable to errors. Patients have to constantly track their blood glucose levels and adjust their insulin dosage accordingly. The problem is that in certain situations, such as during physical activity, glucose levels can fluctuate very quickly. Current measuring devices do not have any prediction algorithms that could provide a reliable prognosis in such cases. However, a too high or too low insulin dose can easily lead to hyperglycaemia or hypoglycaemia and endanger health.

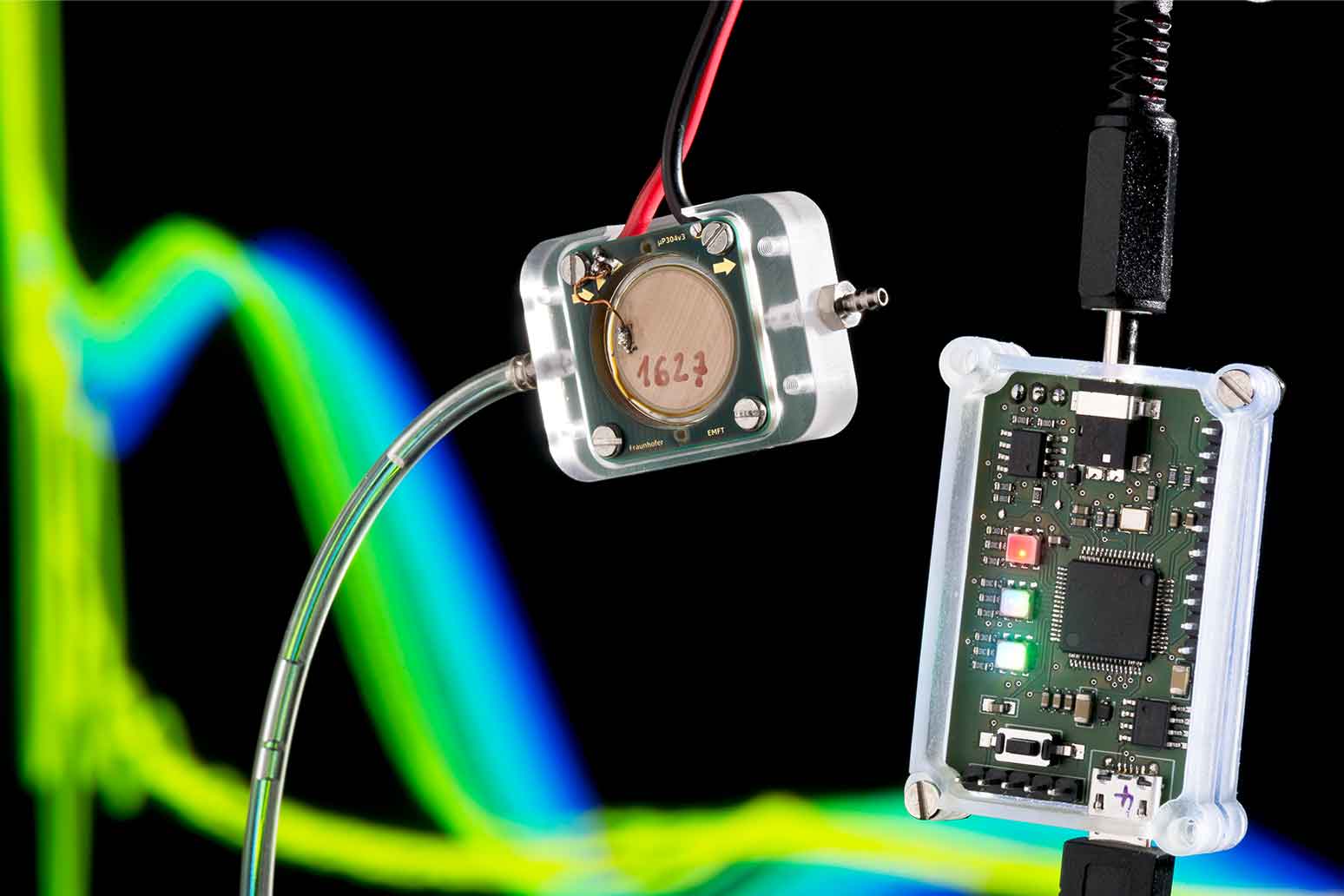

This is where the research team of the EU project MuSiC4Diabetes comes in: The interdisciplinary experts are working on the development of a three-metabolite measuring device. A special algorithm designed to enable the simultaneous recording of the three key physiological signals glucose, lactate and 3 β-OH butyrate. The multi-metabolite control algorithm uses these signals to predict system delays and trigger precise control measures via a sophisticated insulin pump. The pump can deliver the calculated insulin dose intraperitoneally with extreme precision.

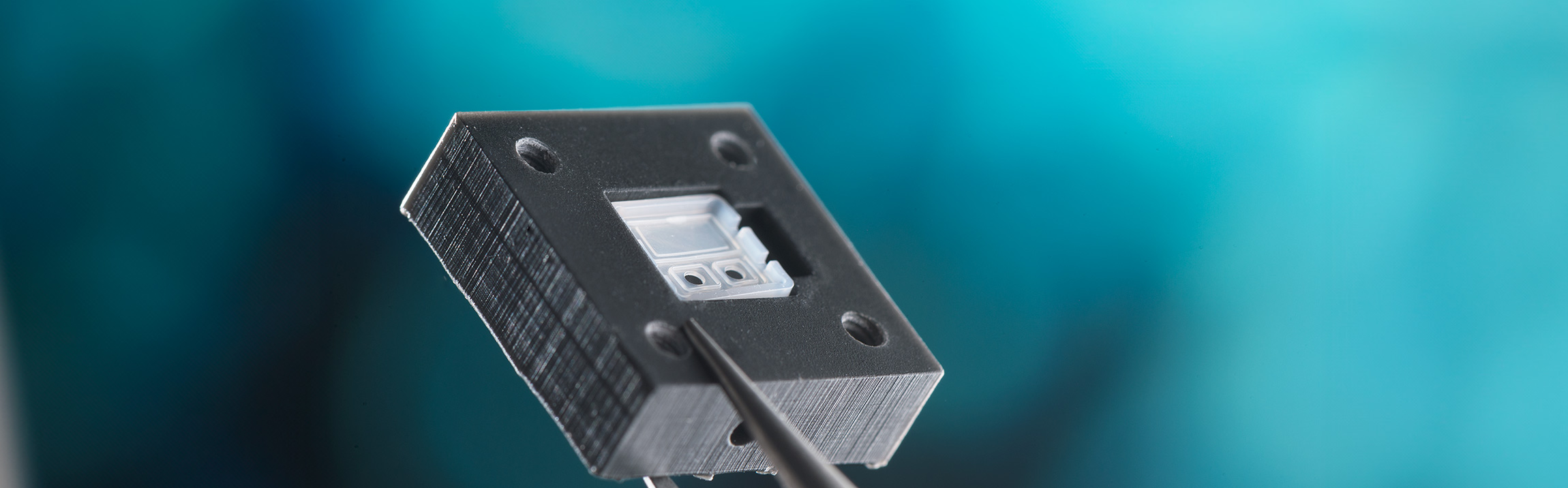

As a backup, the device also provides additional safety functions such as a free-flow stop, which prevents an overdose of insulin in the event of a fault, and a self-recognition function for detecting internal faults, supported by artificial intelligence. Under the project management of Dr. Sebastian Kibler, Fraunhofer EMFT is responsible for the development of the micropump, the safety valve, the self-recognition function and the system integration of the dosing module. The micropump and safety valve are implemented in silicon using micromechanical processes; the micropump chip and the safety valve have an ultra-compact design volume of just 7x7x2 cubic millimetres in total.

The micropump and the safety valve have to meet extremely challenging requirements: with a tiny stroke volume of just 0.1 cubic millimetres, the micropump must not lose more than 5% of its stroke volume when back pressure occurs, and the suction capacity must be so high that the micropump can still pump a gas bubble at a negative pressure of 350 mbar. So far, all micropumps worldwide have failed to meet these requirements. With more than 30 years of experience, the Fraunhofer EMFT has successfully developed this component. The necessary pump technology has been patented and is now available on the market.

In terms of the permitted leakage rates, the micro valve technology will set new standards: The aim is to achieve a leak rate of less than 1/10 cubic millimeter per hour at any given pressure. Finally, the micropump must also be controlled so gently that the insulin molecule in the pump chamber is not damaged, resulting in deposits in the micropump.

The self-recognition function is a disruptive innovation that can be used to detect and compensate for dosing errors, such as the occurrence of gas bubbles. The so-called piezo effect, which can be used both as an actuator and as a sensor, is used for this purpose. By precisely measuring the actuation current (which is necessary anyway), a time-resolved "fingerprint" of the processes in the pump chamber is obtained for each pump stroke. This time-resolved data is trained with the help of artificial intelligence in a training measuring station and the training result is then transferred to a simple microcontroller.

Thanks to this highly efficient and innovative MEMS pump technology, the team believes that a battery life of 10 years is feasible. With regard to the insulin refill interval, the project partners are currently assuming around 3 months and want to use further tests to explore whether this period could be extended to up to a year.

The project is funded under the Pathfinder program of the European Innovation Council (EIC) (HORIZON-EIC-2022-PATHFINDERCHALLENGES-01-04, proposal number 101115233).