With an innovative manufacturing process for large-area, flexible conducting paths, a research team at Fraunhofer EMFT is pursuing the goal of offering an environmentally friendly and resource-saving alternative to conventional production processes.

Sustainable production of conducting paths on foil

With the LEO process, researchers at Fraunhofer EMFT have developed a new approach to fabricate fine conducting paths on flexible polymer substrates in a resource-efficient way. The method requires no lithography process and therefore no environmentally harmful chemicals such as photoresist and solvent-based developers. Instead of the traditional photoresist, a thin self-passivated aluminum layer is used, which is applied directly to a copper seed layer. Aluminum is relatively easy to filter out of wastewater and the small amount produced during the process can be fully recycled.

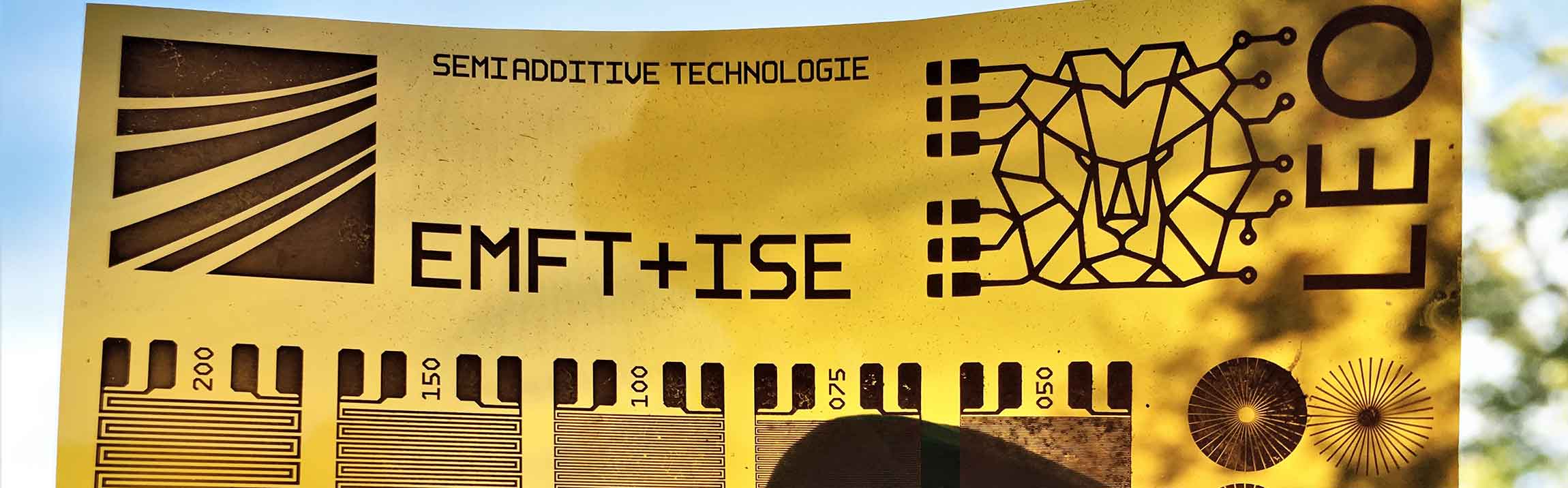

With the help of a life cycle assessment, the scientists are investigating whether the assumptions about the lower environmental impact of the photoresist-free coating process can be confirmed. To this end, they are comparing LEO technology with two established metallization processes: a subtractive etching process and a semi-additive process. All three solutions are manufacturing processes for the one-sided production of copper-based conducting path structures without through-hole plating on foil substrates in a roll-to-roll process. However, the technologies vary significantly in terms of their consumption of energy, resources and chemicals. The resulting effects on the overall environmental impact are described and possible process adaptations to minimize the environmental impact are discussed.

As part of an internal Fraunhofer funding project, the development team, in cooperation with Fraunhofer ISE, has produced large-area conducting path modules for solar cells using the LEO process in order to demonstrate their suitability for practical use.

The reel-to-reel process for the production of printed electronics has a long-established role model: newspaper printing.

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacySustainable Production of Large Area Electronics

In this process, unprinted carrier material is winded up on a roll, with an empty roll on the opposite side. The individual printing processes run one after the other in between, with the carrier material being spooled onto the empty roll on the other side of the press. In the laboratories of Fraunhofer EMFT, researchers use this method to produce ultra-thin electronic components on film. These electronic foils are used, for example, in medical technology as sensors close to the body, in robotics and also in solar cells. The so-called "roll-to-roll" process is particularly efficient for such large-area components.